-

Posts

448 -

Joined

-

Last visited

Content Type

Forums

Events

Gallery

Posts posted by Arkytype

-

-

How does having an "understanding of patent law" matter here?

Either the new Jubilee's bass bin design is protected by a Utility Patent because it is novel, non-obvious, etc. or the Jubilee's appearance is protected by a Design Patent.

What am I missing?

Lee

-

Does anyone know the patent number (as cited in the ad) for the new Jubilee? A search of the USP&TO website revealed no recent patents issued or pending for Roy (Rogelio) Delgado that would describe the re-designed Jubilee bass horn.

Surely Klipsch is not citing Roy's patent #5,898,138 issued on April 27, 1999: Loudspeaker having horn loaded driver and vent.

Lee

-

For all the Klipsch earphone fan boys/girls:

Lee

-

1

1

-

-

One of PWK's favorite greeting to someone he didn't know was to stick out his right hand and say, "I'm Paul Klipsch. I presume you know who you are."

-

Alexander, et al,

Here's a great video showing not only how to construct fabric covered panels but also how to easily mount them to your ceiling (or walls) using a version of the French cleat. I wouldn't mess around with one inch Roxul (or any absorbing material)---get the two inch. You can also space the finished panels away from the walls or ceiling and gain more absorption.

Treat Roxul just as you would Owens Corning compressed fiberglass panels---wear a respirator, long sleeve (disposable) shirt, disposable gloves, goggles or safety glasses, etc. Work outdoors unless you want a room full of particulates from the cutting and handling. Be sure to round the corners of your frames--it'll look nicer and won't tear the fabric when you pull it tight.

https://www.youtube.com/watch?v=XIP2Mix_bwM

Lee

-

3

3

-

-

angelaudio, et al,

Here's an interesting article on the design and construction of a "Klipschorn" using a 12" woofer. Lots of good design data to chew on.

https://worldradiohistory.com/UK/Elektor/INDIA/Elektor-In-1989-05.pdf

If you aren't familiar with the www.worldradiohistory.com web site, it is a treasure trove of downloadable magazines and publications. Back issues of most all the audio-related magazines from U.S., UK and other publishers are but a fraction of the offerings. You can search the entire site (not recommended unless you have hours to see each result) or a specific publication. It will return the year(s) and issue(s) your search term generated.

Lee

-

1

1

-

-

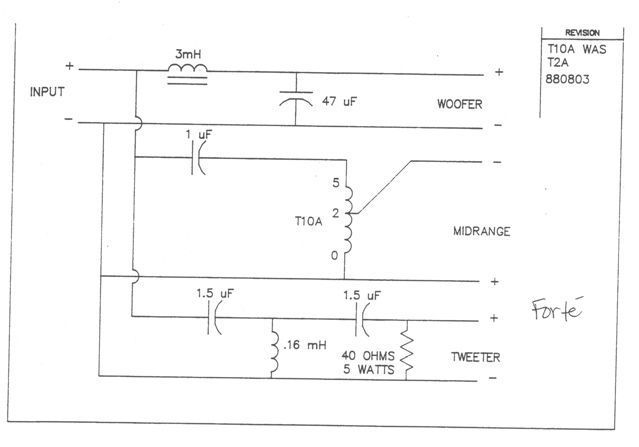

Attached are two crossover network schematics of the Forte I and Forte II I found on the Klipsch forum. I assume these to be accurate.

Note that the circuit topology is identical for both and with the exception of the inductor in the tweeter filter, all passive components differ only in value.

Note also that on the Forte I schematic that the squawker is wired with inverted polarity but not the tweeter. On the Forte II schematic the tweeter is wired with inverted polarity but not the squawker.

Can anyone explain the following:

1. Why invert either of the two drivers in the two Forte models?

2. Why was the squawker inverted on the Forte I and the tweeter inverted on the Forte II?

I looked at a dozen or so Klipsch crossover networks posted on the Forum and found a few networks with driver polarity inverted.

AL-2: squawker and tweeter

AL-3: curiously, all drivers wired "normally".

Heresy II: tweeter inverted

Obviously, changes in drivers or network topology may dictate the necessity of inverting the polarity of one or more drivers to achieve a more uniform frequency response. But I find it curious that the Forte I and Forte II inverted different drivers in the two respective models.

Lee

-

About 40 years ago I drove to the Hope plant to see the anechoic chamber I heard was under construction. When I got to the new lab, I was startled to see Paul rotating (OK, he was spinning) the corner turnstile as fast as he could by hand. I remember feeling the rush of air as each quadrant's dividing wall sped past. He probably "aged" the bearings 20 years in 20 minutes! I don't remember who else was there at that moment but Paul was obviously in his element smiling and telling how the "door" was conceived and constructed. I believe he told me the vertical shaft had Ford truck axle bearings at the top and bottom. Maybe Jim Hunter can fill in here.

I've attached two relevant documents written about forty years ago; the AES paper, Anechoic Chamber with Optional Boundaries co-authored by James R. Hunter and Paul W. Klipsch (Note Paul gave Jim top billing); U.S. Patent 4,387,786 titled Anechoic Chamber Arrangement, also co-authored by Paul & Jim.

Lee

-

1

1

-

-

Wonder if Speakerlab got good deal on those toilet wax rings?

-

1

1

-

-

Let's hope Stereophile doesn't request a pair (CW IV) to review. If they do get a pair, Chief Bonehead should be present when the measurements are taken. Better yet, fly John A. in with his test gear and oversee the measurements in the listening room and the chamber.

Lee

-

1

1

-

-

If you live in the Mid-South, you'll soon learn that cardboard boxes are a residence of choice for the Brown Recluse spider.

Klipsch used to sell the cardboard shipping boxes for their Heritage models.

Lee

-

Thought I posted this version of the 8 cardinal points from a 1976 full-line Klipsch brochure.

Lee

-

1

1

-

-

garyrc wrote, I believe there were 8 principles when PWK first stated them. I searched for them, but couldn't find them.

Looks like Zim. just posted the link to one source. Here's one that Gil posted a few years ago.

https://community.klipsch.com/index.php?/topic/46835-article-eight-cardinal-points-by-pwk/

Note that these are the "Eight Cardinal Points in Loudspeakers for Sound Reproduction" (emphasis mine)---not the top 8 loudspeaker design goals.

I think PWK wrote this IRE Transactions on Audio paper in 1961 to complement the audio research of Bell Laboratory, William B. Snow's ground-breaking 1953 paper, Basic Principles of Stereophonic Sound and others allied in the field of sound reproduction.

-

https://www.klipsch.com/our-technology Scroll down to see The Four Principles of Klipsch Sound.

Looks like Roy's "response" to Stereophile separated Principle 1 (High Efficiency/Low Distortion) into his "sound principles" 1 & 2 and left out Wide Dynamic Range.

¿Qué pasó?

Lee

-

Chris A wrote, One of the great missing links to the loudspeaker engineering repertoire (IMO) is a ranking of loudspeaker performance attributes by measurement type--not based on someone's opinion of what is important, but rather by subjective preference by listener groups on particular loudspeaker types (by listening group preferences), and then an analysis of how the most preferred loudspeakers actually performed, i.e., an approach that is reversed from the engineering literature on loudspeaker measurements.

The person who is perhaps the most responsible for quantifying listener preferences in a loudspeaker is Floyd Toole. He has conducted hundreds (if not thousands) of blind listening tests at Canada's National Research Council with participants ranging from professional musicians to volunteers. I won't spoil the resulting findings. His latest book is well worth the investment.

Sound Reproduction: The Acoustics and Psychoacoustics of Loudspeakers and Rooms (Audio Engineering Society Presents) 3rd Edition

He also is on several informative YouTube videos.

Lee

-

Where we are:

Our power amplifiers (solid state & valve), preamplifiers (passive or active), CD players, DACs, turntables, integrated amplifiers & AV receivers all have one thing in common: Their “sound” is not affected by a room’s “acoustics” which include the dimensions, shape, dimensional ratios, reverberation time, standing waves, etc.

That leaves the loudspeaker which, for the most part, is at the mercy of the above “acoustics” for its “sound” and whose measurements we often question.

Where we’ll never be:

In a perfect world, all reviewers in the audio magazine bidness would have identical listening rooms with the size (ratios, shapes) and acoustic treatment taken from the experience of notables such as Floyd Toole, Peter D’Antonio and the like. Then, maybe at least the objective measurements would be in closer agreement with the manufacturer’s specs. The subjective assessments would, however, be left to the whims, prejudices, and “golden ear wax” of the reviewers.

Where we could be:

If my memory serves me correctly, the factory listening room in Hope has four square corners but splayed side and end walls. I think it was constructed about the same time as the anechoic chamber.

Shameless Aside:

When the chamber was under construction (late 70s?), I visited the plant and found PWK spinning the revolving corner at maybe 40-60 RPM! I can still remember the whoosh of air as each partition went past. He quipped that he was testing the door’s bearings which were from a pair of truck axles. JRH probably was there as well as he drove a lot of the door’s unique, patented construction.

https://patents.google.com/patent/US4387786?oq=klipsch

WWCB (Cont’d)

Anyhoo, I propose that Klipsch get a qualified acoustic consultant and outfit that listening room (Indy's as well) with the proper wall/ceiling/floor treatment that any manufacturer in the loudspeaker bidness should have to highlight their products. The present wall “treatment” at Hope is just sad. What we are striving for is an “ideal” acoustical space using proven solutions; not a few pieces of “acoustical” foam and wall-to-wall carpeting.

Next, starting with each Heritage loudspeaker, measure every electrical and acoustical parameter known using state-of-the-art, calibrated gear, not a laboratory microphone adapted for entertainment use and the decades-old MLSSA testing software John Atkinson uses.

Audio Precision not only manufacturers top-of-the-line measurement gear but also has some powerful, easy-to-use loudspeaker measurement suites. One can make more than a dozen accurate, repeatable acoustic measurements in a few seconds with a single mouse button click.

https://www.ap.com/electro-acoustic-test/

Just think, you could start with a pair of Cornwall IIIs in the corners with the tweeter axis pointed at the microphone (at the listening position); take a slew of measurement; and then gradually move the CWIII toward the center all the while taking comparison measurements.

Of course, these comprehensive measurements would trickle down the product line as warranted. As a “reference” each loudspeaker would be tested in the trihedral corner of the anechoic chamber to compare FR curves and those pesky sensitivity specs with those taken in the listening room.

Finally: The end result of these measurements would be to, a) have a baseline for each loudspeaker model which could (should?) be used in product advertising, and b) could (should!!) be used to refute/dispute an audio magazine’s poor measurement results.

In the case of the AK6 review, if Roy was privy to the poor measurement results prior to publication, he should have (at the least) moved heaven and earth to get those measurements re-done indoors or used the Manufacturer’s Comment section to strongly contest the AK6’s poor measurements.

Lee

-

1

1

-

-

Because of the Klipschorn AK6's bulk—each weighs 220 lb—I drove my test gear the 177 miles to Art's place and measured the speaker sitting on a furniture dolly in his driveway.

So, rather than measure them in situ, Atkinson and Dudley manhandled an AK6 out of the house and onto the driveway? Surely the DRAA MLSSA could gate the room reflections.

-

According to my architectural manuals a 17 foot room dimension is the worst for sound reproduction that you can use for any speaker system.

JJK

Say what?

-

1

1

-

-

Deang wrote, I'm having a hard time believing that Roy didn't shoot for flatest response possibe. I'm inclined the blame the testing methodology.

You have to give John Atkinson credit for making consistent, in-depth loudspeaker reviews. The measurement gear is reliable and gives repeatable results. He's made well over 1000 loudspeaker reviews and his in-depth methodology can be found within the Stereophile archives. Yeah, I'd like to see some I.M.D. tests as well as polars but while those tests would be welcome to fellow Klipsch forum members, I doubt they would be appreciated by most Stereophile readers.

garyrc wrote, I wonder if Klipsch wrote anything in the Manufacturer's Comments section of Stereophile (conveinently buried toward the back of the magazine instead right with the component tested)? I'm curious to know what Roy Delgado would say about this review. Roy? @Chief bonehead. Perhaps he would contest some of their findings, or talk about important qualities they didn't mention.

I would assume Roy was privy to Dudley's review and Atkinson's test data before he responded. His response did not address the review or test results directly but was a curious reiteration of PWK's "four sound principles in order of importance:

High efficiency

Low distortion

Controlled directivity

Controlled frequency response

PWK actually had published his 1961 "Eight Cardinal Points in Loudspeakers for Sound Reproduction" which Gil posted back in 2004.

https://community.klipsch.com/index.php?/topic/46835-article-eight-cardinal-points-by-pwk/

There is a huge disconnect between Roy's praise of the AK6's tweeter and the actual measurement results. I see Chris A posted the review link and an ugly on-axis frequency response.

Maybe Roy would like to post some Klipschorn "dirty pictures" for us to see.

Maybe it's time to rethink the politics of the inflated sensitivity specs, eight-foot bass horn BS and the Heritage "re-styling" decisions.

Lee

-

1

1

-

-

-

The September 2019 edition of Stereophile has a long-awaited review of the AK6 Klipschorn.

The only word that comes to my mind after reading both the Measurements section and the review by Art Dudley is----disappointment.

First the measurements: Once again, a Klipsch loudspeaker does not meet its sensitivity specification. That's odd for a Klipschorn as I would assume its sensitivity was measured in the trihedral corner of the Hope anechoic chamber (see grainy image). You'd think there would be less of the "room gain fudge-factor" Klipsch uses than the 3.9 dB sensitivity shortfall John Atkinson measured.

For logistical reasons, the AK6 was measured out of doors sitting on a driveway. The AK6 frequency response specification is 33 Hz--20kHz + or - 4 dB. For a premium-priced loudspeaker, that spec should be + or - 3 dB or better.

Atkinson measured the AK6 frequency response using nearfield (bass horn) and farfield (squawker/tweeter) measurement techniques. The AK6 frequency response measured: 33 Hz -20kHz +8 dB minus 15 dB (my interpretation of the FR curves). The +8 dB peak at 10kHz is as disappointing as the overall tweeter level which appears to be 3 dB too hot relative to the midrange. I won't comment on the bass horn measurements only to say that even though the back is enclosed, corner placement is, IMHO, the only location to measure the bass response of a Klipschorn.

Second, the listening test: It wasn't clear from Dudley's review how the Klipschorns were located in his 17' x 12' x 8' listening room. Were they on the long wall or short wall?

Dudley writes, I began with the backs of the Klipschorn AK6s a short distance from the front wall--their front surfaces, measured at the centers of the cabinets, were a little more than 3' from that wall, and a little more than 8' apart from each other--and with the the speakers slightly toed-in toward the center listening seat.

Really? Where's my horsewhip? Who in their right mind would listen to Klipschorns eight feet apart and three feet away from a wall?

In 2006 Klipsch turned down Dudley's request to review the 60th anniversary Klipschorn because his (Dudley's) listening room at the time couldn't accommodate corner placement. Did the current Klipsch marketing department considered asking for dimensions and images of Dudley's current listening room?

His current listening room would IMHO be marginal even locating the AK6s on the 17' wall. My listening room was designed around my Klipschorns/Belle and is 24' wide, with 11' high side walls and a 23' vaulted ceiling. The sound quality and imaging is magnificent and is a system not tolerant of poorly recorded pablum.

Unfortunately, I cannot scan the AK6 review and post it----my trusty Epson scanner is refusing to power up. Stereophile will post it soon enough on their web site. Gosh, you'd think Klipsch would have posted the past two Stereophile Klipsch loudspeaker reviews on the web site by now.

Lee

-

3

3

-

1

1

-

-

HDBRbuilder wrote: The options for veneers available changed over the years....when yours were built, ebony and rosewood were still very much in the "availability zone" which changed over time as "the powers that were" decided to avoid offering veneers from "declining tropical rainforest" areas...a decision which never made sense to me, anyway...because if they are gonna cut those trees down to make more farmland, then how is not offering the veneers gonna make any difference, anyway? It was what it was!

When I ordered my Rosewood Klipschorns and Belle in December of 1975, as a salesman for Custom Audio in Little Rock, I was allowed to go to the plant and pick out all my veneers (even the edge veneering!). My only choice was Honduran rosewood as Brazilian rosewood could (at that time) only be exported as a finished product.

The cost? The Klipschorns were $937.00 each and the Belle was $780.00. The salesman's discount was 24%---far lower than say, McIntosh, Nakamichi or other high-end brands we sold.

That 1975 list price of $2,654.00 is the equivalent of $12,635.75 in today's dollar.

Lee

-

1

1

-

-

windashine, you wrote: That's about all I have - this should be an interesting project, take your time.... I'll leave with the only picture of my next project... I'm still trying to figure it out lol

That image of course is of the Libido Loudspeaker Company's Peyronie in distressed Hard Rock Maple. Libido aficionado's just call it The Woody.

Lee

-

Pats3of4,

Except for the front panel which is 3/4" veneered lumber core plywood, my Klipschorn bass bins are constructed of 1/2" plywood. All the top housing is 3/4" veneered lumber core plywood.

You wrote: Im not worried about cutting or the assembly.

You'll probably wear out a planer shaving 1" plank oak to 1/2" thickness. Then if you can accurately cut the dozens of pieces (CNC router might work) , how do you know your construction plans are accurate? There are at least a half dozen "Klipschorn" plans on the internet and all differ either in the angles of some of the cuts or in the dimensions of the pieces.

Here's some Klipschorn advertising copy from the October, 1965 Audio magazine (pg. 77) which describes the construction of the bass horn: The construction of this horn is beyond compare. Nearly 288 screws, plus other fastening devices, plus high -grade adhesives, are used to make the horn as rigid as possible. Also each bass horn is checked with a water manometer to ensure absolute air tightness of the rear air chamber.

Guess you'll wear out a countersink bit or two. 😊

Please post images of your build. progress.

Lee

CES 2021 Klipsch Announces The Jubilee and Dolby ATMOS for your next CAR

in Klipsch News

Posted

If the Klipsch Jubilee ad copy is referring to an expired patent, why not make the same advertising claim for the current La Scala and Klipschorn? Both were patented products in their day.

Klipschorn: 2,373,692 granted April 17, 1945

La Scala: 4,138,594 granted February 6, 1979

Lee