Robbie010

Regulars-

Posts

164 -

Joined

-

Last visited

Content Type

Forums

Events

Gallery

Everything posted by Robbie010

-

Quick update on these.... I did a little testing with the drivers and crossover this week, while I am still waiting for the mid horns to arrive, unfortunately, one of the woofers was dead! 🥺 School boy error, I bought them used a few months ago and never tested them when I got them..... anyhow, every cloud has a silver lining, I’ve now managed to pick up a pair of K33 (round magnet) drivers from Denmark, so the complete speakers will now be using all original klipsch drivers and horns.

-

It’s just some leftover material that I had. I used it to re-cover some old Wharfedale speakers on another project. If I recall it was off eBay for a few pounds.

-

-

-

-

Quick update..... I had a week off, the weather is too cold to be working in my unheated garage! 🥶🥶 Back at it now, the high frequency cabinets are coming together, all glued up today, next step is sanding and finishing then I’ll make the coves....

-

Thanks, the woofers are eminence kappa 15c. I think the clearance looks a little more that it is but yes, I made the motorboard 400mm wide to make sure the woofers fits comfortably.

-

Already got K-77 and K-55 drivers, just waiting on a pair of K401 horns so I can complete the project!

-

Sorry! 😆 I used a glue gun!

-

soldered them.

-

-

Correct way to wire crossover inductor?

Robbie010 replied to Robbie010's topic in Technical/Restorations

Thanks. -

Just about to finish my Type A crossovers with the inductors and was wondering if there is a right and wrong way to connect them? Obviously, there is an inner and an outer wire on the winding so do I need to connect them in a specific way or does it not matter? Thanks.

-

Well spotted, they are the very same 1.5watt SE OTL monoblocks. They were professionally built but not by me! Turntable is a Garrard 401 in a homemade layered ply plinth with an Acos Lustre GST 1 tonearm.

-

Both bass units now done. Will give them a few weeks to fully cure before knocking them back and giving one more coat of polyx oil.

-

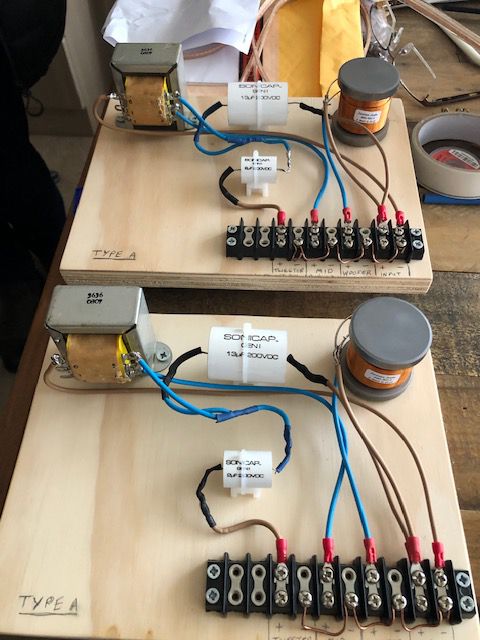

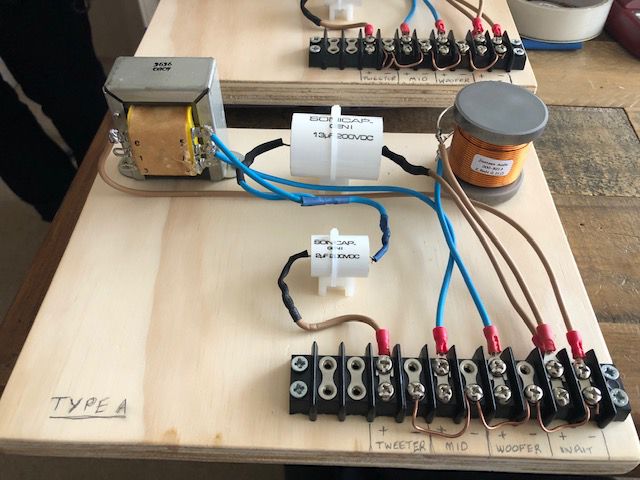

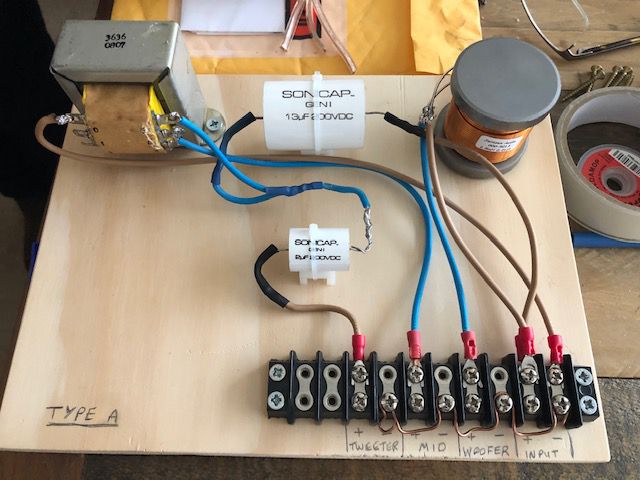

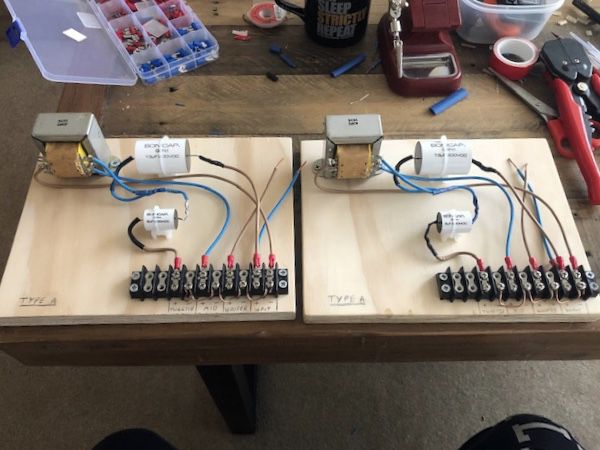

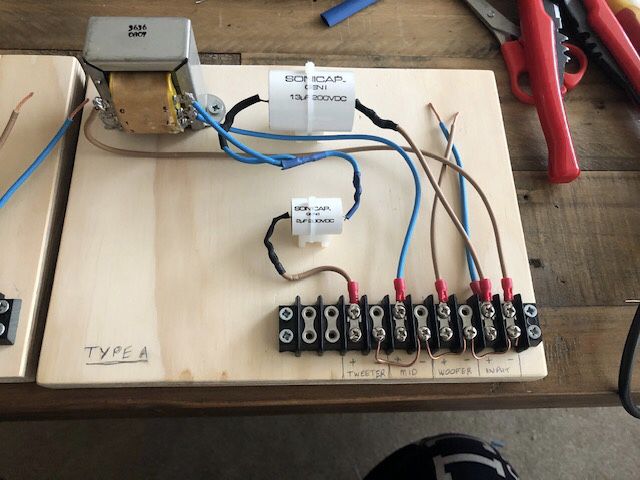

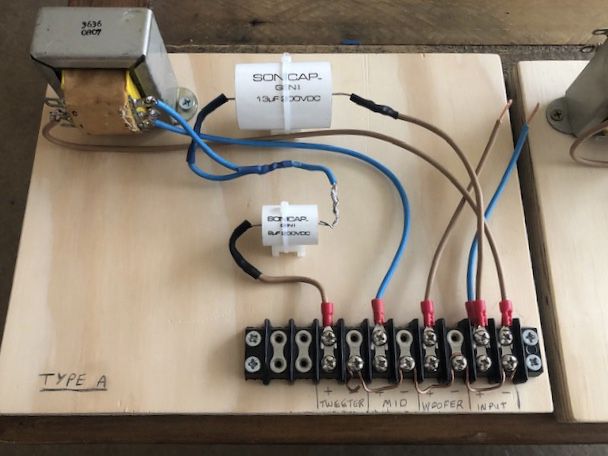

Crossovers almost finished, just waiting on the inductors. Not the prettiest but should do the job.....

-

Evening all, I sat down this evening to layout the components for my Type A networks. Massive thank you to @mboxler for help with the parts (FOC no less), so I am using the 3636 (crites) autoformers and was just hoping someone can confirm the correct connections, as I’m not the best at reading schematics! As I read it: The negative input goes directly to pin 0 The positive input goes to pin 5 via the 13uf cap (which is in-turn connected to the positive connection for the tweeter via the 2uf cap) Pin 4 is connected to the positive terminal for the squawker. Is this correct?

-

I believe it’s Douglas Fir. It does look quite nice with the medium oak stain.

-

- 42 replies

-

- 10

-

-

Good Evening all, I was wondering if anyone has experience of using La Scala on suspended wooden floors with carpet?? All being well, I will soon be installing my La Scala clones, which has got me thinking about the best way to isolate / couple / decouple them. Although the wooden floor beneath the carpet is suspended, it feels fairly solid. However, this will be the first time that I have used large floorstanding speakers on a suspended wooden floor, as my last house had solid concrete (we moved just before Christmas). Do any La Scala users have experience of this scenario and can comment on the best method of isolation or coupling the speakers for the best acoustic results? Thanks

-

I will be building matching high frequency cabinets much like the La Scala II, to house the squarker, tweeter & crossovers. I have just routed out the recessed opening for the woofer binding post’s and the recess’ for the feet to sit in to:

-

Thanks, they are looking pretty good for a first build! I was not planning to veneer them. I’ve been careful to choose birch ply with a nice grain / finish and as few imperfections as possible. However, I do have a number of stains to test and may use a matt poly finish.

-

Thanks. I’m not looking to spend anything really, if I can use something I already have, I will. I just wanted to be sure that the large gauge of the cable wouldn’t be a bad idea.... maybe cause issues with impedance or the likes..

-

I have some spare 4mm2 Audioquest (blue) studio grade speaker cable that I was planning to use as internal wiring from the crossovers to the drivers in my La Scala project. Before I go steaming ahead, is there any reason why using such a thick cable might not be a good idea?? Alternatively, I have some 2.5mm2 OFC speaker cable that I could use. Also, is there a concensus as to whether I should solder the connections or used crimped push-on spades? Thanks.

-

Thank you, I have the tools and gusto to have a go at flush mounting the horn but not necessarily the skill!! 😂 The build is coming along quite well, I should have the bass boxes done this week ready for sanding and staining, then I’ll move on to the high frequency cabinets. I decided I prefer the look of the split cabinet so went down that route, its a bit more work and a bit more wood but I may as well do it the way I want it. There have been a couple of oops moments, mainly due to the poor setup / misalignment of my new table saw but nothing that couldn’t be corrected..... or lived with!