ngen33r

-

Posts

166 -

Joined

-

Last visited

Content Type

Forums

Events

Gallery

Posts posted by ngen33r

-

-

-

-

2 hours ago, babadono said:

So have you tackled RSW-15s?

For selfish future reference.

-

R-112SW plate serial number LH150400882

Had some time tonight to complete another one of these. Repair and full recap. R39 had a meltdown and dried up a few caps and killed the PWM controller power supply. I gooped it pretty good with silicone to dampen the stress on the solder joints so I can let the hot parts breathe a little.

-

1

1

-

-

SYNERGY SUB-12 PLATE SERIAL 06230184

This amp was blowing fuses. The PDC control board failed and took out the mosfets. I had to clean and rebuild the PDC, replace the fets, replace Q5 and TH3. TH3 is almost always bad when fuses are blowing. After the board was working, a full recap was done on the amp.The active crossover was especially fun due to all the damn glue used.

-

21 hours ago, Greg121 said:

I have a Ksp400 and the subwoofer is making a buzz sound. I need to have it repaired. Same thing happen to my other system and Klipsch repaired it. I don’t think they still do repairs. What’s the best way to get this fixed?

This does not at all pertain to this thread and I wish the mods would delete this post. Please send me a PM. It is against forum rules to openly discuss this.

QuoteMany have had good luck with Edwards Electronics over at e-bay. I'm not affiliated nor have used them personally though.

I have also had a lot of success on eBay doing repairs.

https://www.ebay.com/itm/252834002186

-

1

1

-

-

On 1/3/2020 at 8:01 PM, Ron DB said:

This is a little off topic. Would you happen to know the following specs. for the Klipsch R112SW : The high-pass frequency, and it's slope(12,18, or 24db). The boost frequency, level DB amount, and Q if possible. The reason for asking is that I'm powering my r112sw(2ea.) with a Crown xls 1502. One of the plate amplifiers is burned out( amp is now gone) and the other I just removed so I can run them both off the crown amplifier. I know it's a long shot, but I thought if anybody on the Klipsch forums might know, it would be you. Thanks for your time and help.

That information can only be obtained from a schematic. I will have to have a look if Infinity used this same amp. They almost always have service manuals that can be found.

-

On 12/24/2019 at 11:16 AM, Johan said:

Hello,

Same problem with mine.

But so heavy burnt I can't read the value of the resitor.

Can you help me?

Regards.

Johan

The resistor is 820 ohm 3W. It almost always kills the transistor and the surface mount resistors and a couple diodes need to be replaced. The whole board also will need to be recapped after that failure.

-

1

1

-

-

RSW-10 PLATE SERIAL ???

First up we have a RSW-10 and this one already is a challenge, because someone was already inside and changed parts. I have 2 burnt resistors that look to be replaced and might not be the correct value. R44 and R45 on the amp board. I also see that 3 fets were replaced. I need to confirm that Q7 should be an IRF640 and not a IRF530. The amp board is 650027 and it appears that SVS used this same amp in the 20-39PC. Oddly enough the Infinity IL60 uses the same amp board so I should be able to get a good parts reference from that. More to come tomorrow, I'm tired.

Update:1/18/20

I replaced the fets and have the resistors on order. The resistors are .1ohm 2W Wire Wound

ADJUST BIAS PROCEDURE

(Mandatory when any output MOSFET transistors Q3,4,7,8 are replaced)

1. Amplifier should be unplugged and OFF.

2. Remove Amp assembly from cabinet; remove rear plastic cover if present. All wires exiting

the cover can remain connected unless they will prevent you from removing the amplifier or

accessing potentiometers on the Linear board PCB in the following steps.

3. Locate the Linear board assembly (PCB with the output transistors)

4. Adjust R11 and R27 fully Counter Clockwise. See diagram below.

5. Apply 120 VAC power to unit, Turn power switch ON.

6. Verify LED illuminates on the front gain control dial unless you have disconnected the plug.

7. Connect voltmeter set to DC millivolt range to twin pins on terminal J7, on Linear board

8. Verify initial voltage is less then 0.1 mV.

9. Adjust R11 Clockwise until voltmeter reads 0.3 mV + the initial current from step #8.

10. Adjust R27 Clockwise until voltmeter now reads 0.6 mV + the initial current from step #8.

11. Turn amplifier OFF. Disconnect AC power to unit.

12. Remove voltmeter from terminal J7.

13. Replace cover (if present), wires if disconnected, and replace amplifier back into cabinet. -

Hello All

I have been repairing Klipsch subwoofer amps for about 15 years as a hobby. I have decided to start blogging my repairs and eventually do videos of each one. This thread is intended to be a blog and a resource for information. I will try to answer repair questions as best I can. Comments and tips are also welcome, If you do not have the experience or the tools, PLEASE do not attempt any of these repairs. You will only end up damaging the board and it will end up costing more for a tech to repair the damage. If you do not have a high quality vacuum desoldering station (Hakko or Weller) and a current limited mains supply, you should not be working on these amps. These subwoofers do not have any user serviceable parts inside. If you open up the sub or attempt any repair you see in this thread, you are doing so at your own risk!!!

Wayne

-

1

1

-

-

-

-

The boards are 2 layer. If you tear a thru hole off it has to be repaired with a thru hole repair kit and the proper sized eyelet. You can use jumper wires and epoxy, but I consider that a hack job and not a proper repair. Keep in mind this is only if you damage the board. In my experience solder wick almost always tears a pad off of these boards.

-

RT10CH PLATE SERIAL NUMBER 06240152

This amp also suffered from a damaged power supply control board and needed to be rebuilt. Once complete, a full recap and it successfully cooked my 10in test woofer. Note to self lower the volume level before connecting an input signal. Some people have their settings way too high!!!

-

2

2

-

-

-

On 12/20/2019 at 6:09 AM, psyrexer said:

Hello, i have the same power supply unit on my SUB and of course is dead. Can you give a bit more information about rebuilding this board? i need to replace all elements and also replace all 4 mosfets? that should help? I can provide pictures. i didn't find any color change on black glue they are using...

First all the glued components need to be removed and the yellow glue on the board needs to come off.

These boards only have 2 mosfets. You have to do some testing to find the location of the failure. The boards have multiple power supplies after the transformer. You have to start at the end and work your way back to find the issue. Blowing fuses is almost always before the transformer. If you don't have a vacuum desoldering tool, I wouldn't attempt the repair. The boards are made in China and the thru holes rip easily off the board. Thru hole parts don't last very long with vibrations if they are not securely soldered. The only proper way to fix this is to replace the thru hole and resolder. Jumper wires, solder blobs and all of those other types of repairs are hack jobs and should be avoided.

These units are getting old, they should be recapped at this point if you are servicing it.

-

Those bolts are for the WA accessory and they are ONLY screwed into the plate. Either a decoupling capacitor shorted, you have a bad wired outlet, or there is a conductive path to the chassis inside the amp.

-

1

1

-

-

8 hours ago, EpicKlipschFan said:

great idea to start a thread like this. lots of these subs out there that are dead & like many other brands of amps & sub plate amps, the glue they used causes most the issues.

i have the rw-12d & am sure the glue on the area you have circled is what killed mine. im in the process of cleaning it up & was wondering if you can confirm any other locations that had the bad glue? is it the yellowish-tan glue around the caps & other parts that is the main issue or the bark brown stuff on that small board you have circled? also can you say what you use to remove it? its nasty stuff & so far only physically chipping it away has removed it. mine blew the little round green thermistor too.

Anywhere that the glue has started to turn brown needs to be fully removed. The best way to remove it is to use hot air at 150C and a dental pic to remove it when it gets soft. The control board needs to be removed and thoroughly cleaned. The Chinese capacitors on these are about at end of life and should also be replaced, especially if you never power the system fully off. The switch is installed for a reason. The standby mode does not fully power off the unit and I know 99% of us do not turn our subs off.

-

1

1

-

-

-

Hello All

I have been repairing Klipsch subwoofer amps for about 15 years as a hobby. I have decided to start blogging my repairs and eventually do videos of each one. This thread is intended to be a blog and a resource for information. I will try to answer repair questions as best I can. Comments and tips are also welcome, If you do not have the experience or the tools, PLEASE do not attempt any of these repairs. You will only end up damaging the board and it will end up costing more for a tech to repair the damage. If you do not have a high quality vacuum desoldering station (Hakko or Weller) and a current limited mains supply, you should not be working on these amps. These subwoofers do not have any user serviceable parts inside. If you open up the sub or attempt any repair you see in this thread, you are doing so at your own risk!!! -

-

16 minutes ago, CECAA850 said:

If you're going to mess with speakers and subs a DVOM is a must have. They're cheap also.

I second this and my personal favorite is an Radio Shack TRUE RMS that I grabbed on eBay for $15. Either way I will confirm the measurement when I am home from work, but I am 95% sure it is 4 ohm.

-

Is R39 on the board burnt? and I'm interested in the amp. I have a driver at home, I believe that they are 4 ohm but I will measure it to make sure.

-

RT-12 Plate serial number 06440047

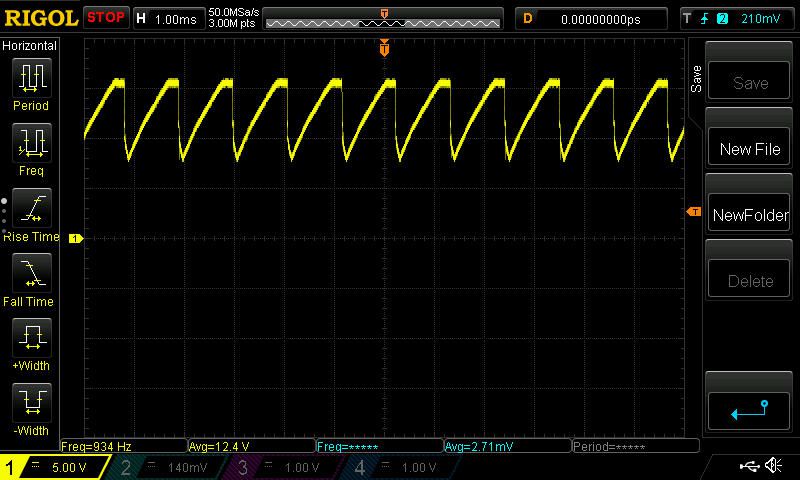

This amp was not getting any power on the secondary side of the transformer. A know weak point is the controller board 660045-1 failing. This was not The case with this amp. Pin 2 connects to the power supply that is on the board. This pin had voltage, but also a lot of noise. This noise will not let the supply start or properly regulate. The only way to see this is to look at pin 2 with a scope Pin 3 is the common and connects to the negative side of the rectifier. Pin 6 will have over 300V present. If you are poking around and slip, you will do some damage or worse shock yourself. The noise points to a bad capacitor, which is the only thing that pin 2 connects to. Replacing this cap brings the supply back to life. The whole supply will be recapped and it should be good to go.

-

1

1

-

Sub-10 / Sub-12 / RPW-10 Repair Blog

in Technical/Restorations

Posted

SYNERGY SUB-10 PLATE SERIAL 05420831

This one looks a little brown and crispy. The back of the red film capacitors also has some nice black magic smoke on it. Q5 is turning brown from overheating. This will need a full recap, removal of all the glue, Q5 and fets replaced and rebuild of the PDC board.