-

Posts

1086 -

Joined

-

Last visited

Content Type

Forums

Events

Gallery

Posts posted by germerikan

-

-

When I do chicken, roasts, ribs or pork steaks I vacuum them 1 or 2 days beforehand.

Vacuuming them really gets the rub or marinade pulled into the meat.

I will have to see if the Chipotle can be sent to Germany, this is the one thing I am missing.

-

This is a pilot program, it is supposed to go directly in the inbox instead of "other" folder. Supposedly only in the US now, I have not run across it yet.

So much for Facebook is free, and always will be.

-

-

Great link Schu!! You were right!!

-

Man that had to take some time!!! Thanks for the heads up..

-

So funny and so true

-

I would say that is very big!!

-

-

[:|] Those were some chaotic streets, would be a field day of jaywalking tickets now a days..

-

I heard this was THE jazz album (or album at all) to have in you collection. I heard some tunes on youtube and it is just my cup of tea!!

$350?? man that was a good investment!!!

-

[

] Thanks!!

] Thanks!!The corners were an eueka moment. I am a bad woodworker and the corners were not flush so I took some 3mm copper plate and made some inlays. I just had to Dremel the corners down a little. Now it looks good. The feet are from Viablue, not that cheap but it sits well, you do not have to sneak around so the LP does not skip and they look cool!

Yeah I like the in wall stuff. My wife hates cables so when we renovated I asked the guy that did our drywall to make these shelves for us. They are accessable from the hallway on the other side and everything looks neat. I will be changing this though to one big hole with a cabinet inserted and adjustable shelves. Then I have more possibilities with different sizes.

-

He shoots he scores!!!! My first Jazz LP!!!!!!!!!!!!!!!!!

It was unfortunately not 100% clear if it was the stereo or mono version since the number was S BPG 62066.

I don´t care though, then it is my first mono lp as well!! [

]

] -

I was not sure if it was a good pressing or not, I will definatly try to get this one

-

HELP I have 20 minutes, a 1960 pressing from Miles Davis kind of Blue for 25€ would it be worth it???

condition 14 from 15 points

Pressed in England

Any Ideas??

-

Dag nabbit, just got a new Deck and was wondering what new records to buy when I come across this thread. My wife and I feel big band and jazz have to be an LP [

]

]Lot of nice suggestions here and I am already starting to look for bargans...

-

You are welcome!!

It is finally at home with all the trimmings

Here it is playing Brothers in Arms

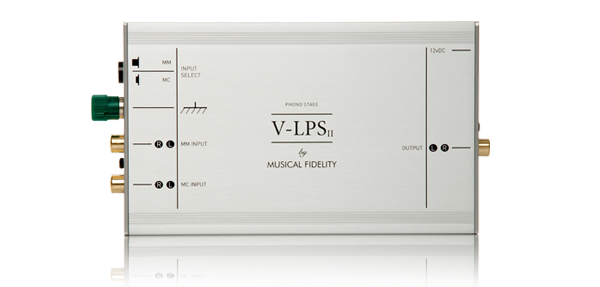

Note on the Musical Fidelity V-LPSII. If you are on a budget and want to try a phono stage which does not break the bank this is the one!! Dead quiet and gives a really nice playback. Not to warm but is definately an Analog sound. I am very happy with this purchace.

-

Double post

-

So it is done,

The oil/wax mixture is from osmo. Nice sheen

and the wood still feels like wood.

I have changed the corners a little since the spaces at the joints were annoying me.

Here is the finish, I like it a lot more in person.

Connectors here

Here is the internal wiring, cable from sommer cable

Well that is about all for now, I still have to get spikes for it and a phono amp. The spikes will be from

Viablue, the black QTC

The phono amp I am looking at is the Musical Fidelity V-LPSII supposed to be real good for around 150€

-

Fröhe Weihnachten und Guten rutsch ins Neuen Jahr!!

Best wishes aus Germany!!

-

I know the vinyl engine has them as well, I was trying to find a way to print it at the right size. You did such a good job cutting it I thought you used a cnc mill. Nice work I cant wait to see the final product.

Thanks this is my first plinth.

Just go to a copy shop and they can print it on a larg format printer should not be to expensive. If it is the same one that I have you have to scale it to 201% you could also PM me and I could give you the 1:1 it came out perfect and is the right size for all Duals with 3 feet.

Here was todays work.

Tomorrow or Monday I will be sanding 2 or 3 times and getting ready for finish. -

For what its worth... I'm really enjoying the photo's that you are posting....

Thanks it is good to see someone is actually looking at them.[

]

] -

How did you go about cutting out the opening for the table.

I got a diagram from the German Dual website with the layout. It was a small tiff and I just exploded it to the right size and had the cut I needed. Than used a 10mm drillbit on the curves and jigsaw for everything else. Where the feet go in I used a 20mm bit and routered them out to 21mm with my Dremel, fits perfectly.

If anyone else has a Dual with the 3 feet I can upload the PDF I made it is 1:1 and if you print it out by a copyshop with a large printer it makes it much easier. Luckily we make the software for these printers and I have one (actually several) at work.[

]

] -

What song is played in the video? Here in Germany it is blocked due to lack of music publishing rights.[

]

] -

Here is the work for today getting closer:

I think this is coming along well, another 2 days and it should be finished!!!

FaceBook charges to deliver some messages

in General Klipsch Info

Posted

Yeah, but I did find a buddy from the Army who I had not spoken with in 20 years, also my first Girlfriend when I was in the army lol