-

Posts

4761 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Events

Gallery

Posts posted by Dave A

-

-

1 hour ago, jjptkd said:

Could it be that BB is really the only choice for pro gear because it is the only material that can hold up and have nothing to do with sound quality?

I get what your saying, I myself have been a re-seller for many years bought and sold lots of Klipsch gear but I can tell you from my experience I have seen more mint like new 25+ year old mdf cabinets than I have seen wasted ones.

It is because the pros know they can have both durability and quality sound. Certainly there are more nice MDF cabinets around than bad ones but that has nothing to do with sound quality or durability. Those Klipsch speakers are revered by most owners and well taken care of but I see the sad side of what happens to those that suffered one way or another and MDF offers nothing better in sound but all kinds of problems with durability. Even the pretty ones often have screw holes stripped out and rarely do I see that in plywood.

1 hour ago, DizRotus said:“Around” as in alive, but not “around” as in control of the company he no longer owned.

Precisely.

-

On a serious note here I had read that using two caps to reach a final value could reduce ESR. Combining a 10uf and 15uf gave me half the esr of either cap separately and half that of the 25uf on it's own.

-

8 hours ago, ZEUS121996 said:

Dave,

You seem to have an imbalance in your cap distribution. I see 6 black, 5 yellow, 4 red and 1 blue. It's no wonder you can not reach superiority in performance when you have no balance. BUT! BUT! You can correct this simply by adding 5 blue, 2 red, and 1 yellow soldered in series. Now get it done and report back in the morning! You have been given a simple task so get to it! I fully expect The Completion Backwards Principle to be fully deployed upon completion.

WTF did I just say?

Mark

Oh, well I though the general principle was to keep adding what you had on hand until the shelf was bare and tune it by ear as you went. Remember though that color imbalance on the caps can be neutralized by opposing color ties snugged to the outside and a little experimentation and checking with your earaudiometer will yield a superbly balanced output.

-

4 hours ago, MechEngVic said:

That almost looks like plywood layers sandwiching a particle wood center.

You are looking at the end of the wood grain on that ply and not parallel to the wood grain which makes it look like that.

-

5 hours ago, HDBRbuilder said:

The problem is a combination of all the extra cross-grain cuts involved with so many plys involved in Baltic birch PLUS the extra layers of hardened glue for all of those plys...generates extreme heat And dulls the edges at the same time...it is one thing to be a hobbyist builder, quite another to have to do production runs of parts....production runs is the key to the issue which is seldom noticed much by the hobbyist builders who don't NEED to make runs of many pallets of parts for what few they build. Remember: Klipsch doesn't lay their own veneers, the MDF is veneered at its source. So, if they used veneered Baltic Birch, then it would ALSO have to be veneered at its source....and shjpped to Klipsch in pre-veneered and edge-banded matching pairs panels, and THAT would be EXTREMELY EXPENSIVE...plus addressing the quality controls at the source would be almost impossible! I mean that would be GENUINE "global out-sourcing" for those panels! Look at it this way...how many times have you ACTUALLY gotten baltic birch sheets that were even square at the corners, yourself? Think about that for quality control of pre-veneered Baltic birch panels at the source....make sense? Thern add in the issue which Baltic birch has ALWAYS HAD, thickness of the sheets being spot-on...good luck with that! Even within the same bundle the thickness can vary quite a bit, which will be evident to the eye when building mitered joint boxes!

I had no idea they bought pre-veneered panels. For some reason I thought veneer was done in house.

Currently working with a cnc router shop in Nashville that has a 5' x 20' table and there are a few other routers under their roof too. They keep them busy and so I would say they qualify as production and it involves many different parts. When they get a piece of Baltic, which as you say is often not quite square, they throw it up on the vacuum table and there is a laser origin finder that takes just a few seconds to align to the sheet and make sure there is enough for a true square corner that can extend the full width of the sheet in both x and y. Tooling for them is not a problem and they cut baltic all day long as their major source of income is and has been speaker builders for a long time. When things do wear out there are probes for tool setting like I have on my Haas mill and setting tool diameter and length is just seconds to do. Takes longer for me to change an endmill out than it does to measure the new tool relative to X Y Z. Whole process is maybe 4 minutes and if you buy the right carbide for the job does not happen until you have cut a lot of product.

I would not want veneered BB and when I talk about BB I mean raw as I think it is pretty on it's own. I have seen thickness vary on BB which has an acceptable tolerance range that could cause trouble but then again so does regular plywood. I assume Klipsch would order sanded plywood to tight tolerance to avoid that problem since they must buy it by the truckload.

-

7 hours ago, HDBRbuilder said:

SIMPLE ANSWER IS production costs would be higher due to the wood costs AND the cutting tool costs. Density and glues used in Baltic birch wear out cutting tool edges rapidly, and require replacing them much more often! More labor cost is required (for replacing saw blades and router bits), in addition to the costs of quickly worn out cutting edges on cutting tools. BUT I STILL PREFER BALTIC BIRCH OVER MDF!

Somehow I would have thought the price of good veneer and the labor to put it on would be much more expensive. On the tools are you talking HSS or carbide? The advances in carbide would make today's cutters last much longer.

-

1 hour ago, richieb said:

So, what we have here, take your pick, are games from our youth -a) pick up sticks

b) tinker toys

c) exploded Rubik’s cube

and / or

d) Rorschach test

e) rare Picasso

or / and

f) pile of shyte

It is an artistic rendering of a crossover and your total lack of discerning artistic appreciation is noted.

-

1

1

-

-

3 hours ago, Randyh said:

ok so why not give klipsch customers the option to have cabs made out of BB ---just charge them the extra ------but to buy a pair of Lascala-Khorn-CW made of MDF , ----------somewhere along the line these wont last as long as BB

No actually it should be charge them less since they could offer them in raw birch like they used to and not have the considerable expense of veneering something.

-

I have never had the privilege of owning true Baltic Birch Klipsch. Plenty of Birch faced plywood yes but never the real deal.

-

34 minutes ago, CECAA850 said:

Hell, I just finished that last one. I'm working on about 4 bottles of Brians stuff now.

So you are telling me a little bottle kicked your butt for six months!!! Tell me how long Brian's bottles will last.

-

51 minutes ago, CECAA850 said:

Saute sweet red peppers then cook them with scrambled eggs.

I have some hot sauce for you if you don't wimp out.

-

Down to $3100 and apparently those ridiculous offers are starting to sink in.

-

4 minutes ago, glens said:

So put a resistor in line before any other elements, like in the Jube schematic: to taste. Try the range given in that Jube schematic. Was it something like 2 - 4 ohms?

I don't know and I will go have a look.

-

12 hours ago, risingjay said:

The schematic that CANT posted is my one crossover that doesn't look like OEM because there is no PCB. My other six have the autotransformer, polyswitch and resistor.....don't know why. One says KPT-904M-B the other six say KPT-904M.

Do you have an xilica or access to one?

I have a xilica. I have fiddled with this setup and bi-amping these but the ones I am fixing to sell I want to be run with passive crossovers. 90% of the people I sell to want plug and play only.

-

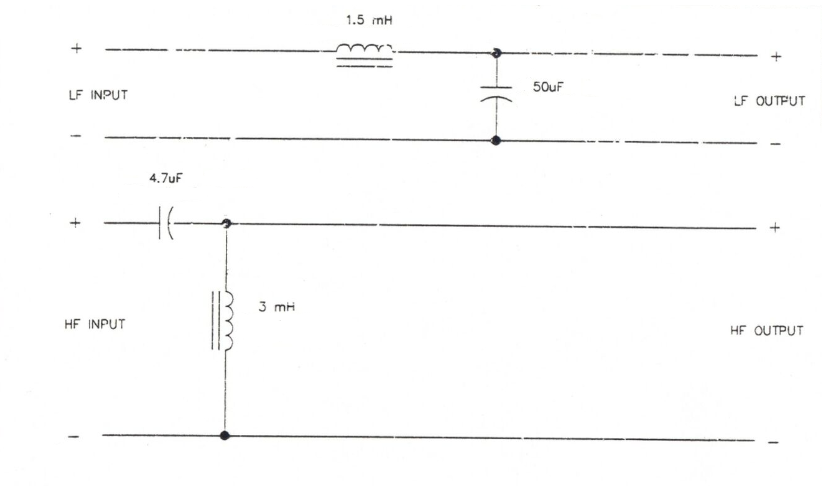

16 hours ago, CANT said:

Why not just use the actual 904 crossover design?

or if you wanted you could use the KPT942... which replaces the 50uF with 75uF and the 4.7uF with 6uF (inductor values don't change). I don't have a pic of the schematic for the 942 but I do happen to have the physical network. The 942 was obviously intended to be used with a 402 and not a 510 but it crosses high enough (500-600Hz-ish) to potentially be used with the 510? Stock 904 crosses at 800Hz according to the spec sheet I have, always looked more like 900Hz-ish whenever I played around with it?

The OEM crossovers I have for this are bright and I have been told this is because they were meant to go through a movie screen and not be sitting out in the open during use. They are bright with the OEM crossovers and annoyingly so. I don't know the lower limits to the 510 horn but Klipsch says 900 hz for HF crossover. I wanted to try to get down to say 650 if possible as what I have been told is that the more you can make the horn do within it's inherent limitations the better off you are.

-

10 hours ago, Randyh said:

I was under the impression that Heresy 1 Was made with Birch veneered plywood -and Heresy 2 -------MDF

I was too and I have only had one H2 and it was MDF and the biggest reason why I have stuck to H1's. I like the bigger tweeter lens size though and may just make a set out of BB this next month or so.

-

Thinking about food and the way things were around here some time ago. My neighbor has a large log smoke house he says may go back to the mid 1800's. Big Yellow Poplar logs can do that by the way and not rot away. So when people HAD to rely on themselves smoking and salting gave them food for lean and good times. Another neighbor of mine had what was left of an old Kerosene refrigerator. No electricity and it worked off a small flame. From the 30's which were lean times.

-

2

2

-

-

I have been fiddling with making crossovers for these 904's + 510 horns I have here. So I go to places like Erse and DIY and others to look at crossovers and trying a 2nd order HF Butterworth last night was really bad. I followed the recipe and it showed the same components for the HF and LF sides and the only difference was where the capacitor was placed as in before or after the inductor. For a 659hz crossover it shows to use a 2.77mh inductor and a 21.something uf capacitor. Sounded terrible and yet this was the recommendation. The original 904 type bass bin I worked on was from a KP-450 and then a KPT-456 both of which had a 2.75mh inductor and a 50uf poly cap. Nothing at all like the crossover calculators said to use. Where is a good place to go to start learning about this?

I have analytical tools like REW and TrueRTA and the UMike here. Is the best way to start doing this might be to set it all up in the Xilica first and then take that and somehow use the settings in the Xilica to determine components for a crossover and how do you do that? I am hampered by distance from people I know who could help so trying to find a wise direction to seek here.

-

"Kung Fu" noodles from the asian food store. Potatoes and macaroni. Jasmine rice a long time favorite with lots of eating from a 50# bag. Split Pea soup. When we first moved to Tennessee and were really broke Bambi worked just fine too.

-

3

3

-

-

14 minutes ago, garyeanderson said:

I like the BB plywood, I use it when it make sense to do so. I happed to buy this sheet to help a friend with rebuilding of an English sports car. I cut the patterns he gave me and I had most of the sheet left over. The recite is what I bought 3 years ago, the picture is what it left now.

I got a quote yesterday on 4' x 8' 25mm BB for $84.20. That sheet is about all I care to lift up and move anymore.

-

17 hours ago, oldtimer said:

That's beautiful.

It finishes up nice just like it is with satin spar poly. The edges of the plywood are great contrast to the sides and I like the overall appearance as much as veneer. Unlike veneer which can be real easy to sand through if you have problems the outer layers of BB are more forgiving.

-

1

1

-

-

1 hour ago, Marvel said:

I'm still hoarding speakers... can't seem to help it. 🤪

I look at it as running a rescue mission.

-

1

1

-

2

2

-

-

7 minutes ago, twistedcrankcammer said:

And I can MAKE ammo, but I'm not stupid, I put back more than enough a long time ago!

I have a whole hell of a lot of gun friends from personal relationships and over a dozen sites I frequent and from what I am hearing, this is not happening nearly as much out in rural communities as it is with City Idiots.

Just my take... Roger

You got that 100% right.

-

1 minute ago, tigerwoodKhorns said:

I agree that you should be a critical thinker, but be careful. The news tries to scare the shit out of everyone to get viewers. We know that. But there is a big difference in the news conflating an issue and governments and private businesses taking extreme measures that go against their citizen's freedoms and profits, respectively.

Nations do not just go into quarantine and airlines do not cut 40% of their flights on news hype. That can bankrupt them.

Here at home. MGM Mirage and Wynn resorts are temporarily closing (not all of Las Vegas, but these are two huge companies). The casinos do not shut down.

Here is the story, Fox news, go figure.

I see that too and do not close my eyes but so far I have seen nothing that warrants all this. Of course the answer to that is that the measure worked and that is why the death toll was small. I get that but when the network news is built on so many provable falsehoods, fake news, which part do you believe and why should they be believed this time?

Remember the day when if you did something to yourself only you were to blame? Today these businesses have to shut down or face lawsuits later from people who knew the problem existed but went there anyway and then sue because the bad thing they knew could happen did happen. I like today's tech but miss the moral compass of 50 years ago.

-

2

2

-

Corona Virus Disease/(SARS-CoV-2) II

in Lounge

Posted

Logic and common sense do not have a part in this manufactured crisis. Please do not try logic and common sense as it is not appreciated. I think I have just lost all interest in watching the hype overtake reality and ponder how all these hand wringers worry over a few deaths from the Wuhan virus but do not collapse into quivering masses of terror over the 20,000 plus who will die from flu in the USA this year. Somehow when the news media did not go all ape s--t over the 60,000 plus deaths in the USA alone in 2017-18 these current worriers did not live in fear. How can that be? It saddens me that so many can be told what to think and then do so without any critical analyses of the topic at hand.