-

Posts

575 -

Joined

-

Last visited

Content Type

Forums

Events

Gallery

Posts posted by No.4

-

-

@Chris A maybe a stupid question, but I was under the impression I could output the sweeps from directly through the MiniDSP?

-

My computer is picking up the MiniDSP 2x4 as the output. It may be the settings in the MiniDSP software. The instructions are just ok. I’m sure I am missing something simple. Usually the case. Just super frustrating!

-

Well the previous comments are disappointing. I did not realize there was such a big issue with these. I would have waited if I had known. Oh well.

I’m trying to get some measurements now, but I’m having a hard time getting the sweep to output. Everything is set up right as far as I can tell. I must be hung up on a setting.🤨

-

21 minutes ago, Chris A said:

Good instincts, but I'd leave it alone for now. You can report it to ESS and see if they'll send you another diaphragm, but don't hold your breath waiting for it to arrive. Assume that if you try to remove the diaphragm, it will fail.

This diaphragm was from the more recently ordered pair. The first pair I ordered was from 12/2018. They look perfect.

well, when the kids finally wake up I will fire these up!

-

1

1

-

-

I am finally getting round to doing some measurements (hopefully) but I have some questions before I fire these up. First I measured my stacks with my DMM one measures 7.0 ohms and the other 10.85 ohms. I’m not sure if this makes a difference at this point as I have read some of your comments about break in, but... Then I did a visual inspection of the drivers and noticed an anomaly with one of the drivers in the 7 ohm stack. It looks like one of the corners of the diaphragm got pushed down a little when it was installed at the factory. I took the best photo I could. My first thought is crap I probably need to tear down the stack and try to re install that diaphragm, but I am worried about trashing it in the process. Given the current global environment I probably would not be able to get another for some time. Any of you heil experts have any advice on that one?

I am worried if I leave it, it will cause distortion.

-

1 hour ago, Thaddeus Smith said:

NIce! I found 500hz to be a good crossover point before I went forward with Chris' method of full range passthrough + PEQ's.

Good to know, and do elaborate.🙂

-

-

I have finally finished building the core of my wing set up. I have everything in place in my room, all amps wired, Umik and MiniDSP connected to the laptop etc. I have set the input and output parameters on the MiniDSP hd and a basic 400hz crossover point. I am hoping to be able to get some measurements going maybe tonight. It is surprisingly difficult to find the time right now for hobbies even with all outside activities cancelled. I have been busy trying to preserve the sanity of my family as cabin fever sets in!

I do need to read back thorough this thread a little and double check some details. I’m hoping to hear music soon though and get the heils broken in.

-

I like my Emotiva ERC-3. It’s built like a tank.

-

2

2

-

-

-

I’m not sure how high these will crossover, but, I have heils on my mind so.. How about splitting the two halves apart 6” or so and installing a AMT stack assembly in between the two halves with wings extending out from there. The di-pole effect would undoubtedly suffer, but maybe it could be absorbed.

just a thought.

-

1

1

-

-

I am really looking forward to doing some listening. I am not that far away once all the rest of my components arrive. If this is even just as good as my current setup it will be a win. I have about the same amount of money in four heils, a mini DSP and a new amp as I do in just my current passive networks. Not to mention the mid horns, mid horn drivers, tweeters etc.

-

1

1

-

-

11 minutes ago, Rudy81 said:

I wish. I'm on my fourth pair!

I wonder if he would entertain a group buy if there was enough interest.

-

4 minutes ago, Randyh said:

nope , I just posted a cart , the Sale price shows up here , don't wait , make an order , it might just work

https://essspeakers.store/23024035/checkouts/531eea0fdd2378c689823c1637cdd9f8?locale=en

It showed up as $340 for me.

-

Alright second pair ordered.

I’m pretty sure you guys work for Ricky😉

-

2 hours ago, Rudy81 said:

That is still a decent price for what they do. I have heard they were in the $400 category some years ago.

Yeah, it’s not bad. I Just should not have waited. I did however just order an Emotiva A-150 to power the bass bins. I had a $30 coupon for signing up for text alerts. So that makes me feel a little better 😎

-

1 hour ago, toolz said:

Sale price is gone. Original Great ESS Heil Air Motion Transformer™ I - LARGE $170.00

Regular price

Oops, looks like I waited too long to order my second pair😔

-

Those look awesome! I’m glad those horns are going to good use!

-

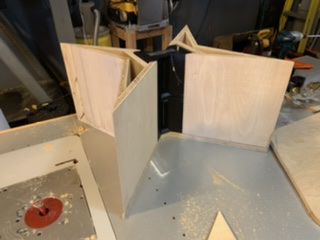

This thread has been quiet for almost a week, so I will throw in my two cents. I have been working on a set of 12” wings for this project and have made some decent progress. I have one setup complete enough to begin testing soon. I took a slightly different design approach to the wings. My goal was to match the esthetic of the La Scala bass bin. Whether or not I have achieved this visually and more importantly sonically remains to be seen. I worked with plywood for these wings, which I generally don’t do for assemblies like this, so that was new. Overall I think the ply is a good material, but it did not like some of the extreme angles I was cutting. This is not surprising, and any issues would be covered by veneer in the final product. I also built a glueing jig to aid in assembly, and to promote uniformity/repeatability between the assemblies. Of course the first waveguide half I glued came out slightly out of level. The jig worked very well once my base panel was properly leveled/flattened. I probably need to make some more adjustments to the jig to get it just right. I may try a different core ply too, just to see if it likes the angles a little better.

If all goes well I hope to be testing this assembly in room this next week. I will be using my current tube amp to power the heils and a spare receiver to power the bass bins. The receiver on the bass bins is not ideal, but it is all I have right now. I would like to find a good inexpensive amp for the bass bins. I would really like to build an amp for the bass bins, but that will have to wait as I am backed up on projects right now. Somehow this one made its way to the top.

-

6

6

-

-

That is some solid progress!

-

-

2 hours ago, Chris A said:

Reportedly, the life of the diaphragms is decades (more than 35 years according to a German source that tested an old one recently), as I've seen more than one person state that they have ESS AMTs from the 1970s that still work.

I have pair that are from roughy 1972 that see daily duty. As far as I know they have the original diaphragms. I can’t say for sure though because I was manufactured in 1977.😀

outside of the diaphragms I don’t see how you could damage the magnet assembly.

-

1

1

-

-

1 hour ago, glens said:

The Modi 2 Uber has a DC input jack and a supplied wall wart. At least that's what the manual says.

The 3 does as well.

-

Double Stack ESS AMT-1 with Wings--Possible Kit for Heritage

in Technical/Restorations

Posted

Ok, I will run it that way. That is actually how I had it set up originally like I would when taking other measurements. I will try that.