-

Posts

575 -

Joined

-

Last visited

Recent Profile Visitors

4543 profile views

No.4's Achievements

Forum Veteran (4/9)

354

Reputation

-

You would be at the wrong end of IL, GLWS.

-

I am 10 minutes away…..pretty sure my wife would kill me though.

-

To answer the question in the thread title….it depends. The internet provided humanity with a wealth of documented knowledge, at everyone’s fingertips, but we twisted into something terrible out of greed. If it continues down the same path, then in my opinion, no. I am forced by necessity to have a smart phone, and sadly much of my current day to day requires it. I have less and less interest in the internet as time goes on. This forum is as close to social media as I get. Aside from the reference material, I could do without it. The phone was obviously first, the answering machine second. The internet killed the ability for people to be free of the instant contact tether.

-

I wanted to build a get set go, but by the time I got around to it Shannon was no longer selling boards. Real bummer. I did build a clementine which has been my daily driver for many years now. Great designs.

-

I typically use the IEC inlets that have the fuse holder and appropriately rated power switch built in as well. Everything I build is heavy, it is nice to not have to fight a cord while moving amps around when necessary.

-

My apologies, I was probably thinking of k510s. That’s what I get for too much multi tasking!

-

I am wrapping up some of my winter projects, and starting up my spring projects for this year. I need a project for late summer, fall next winter….I plan ahead. I am looking for a K402. I only need a single, either version, preferably the mumps version, but not critical. A broken horn is fine. (I seem to recall a thread were someone’s horns either got damaged somehow or broken in shipping, those would work) I am in no hurry, just testing the waters. I would prefer to stay local so I can pick up potentially, but that is a tall order. Localish is okay. I am 2 hours from St. Louis, 2 hours from Evansville In and 45 minutes from Paducah. Before the end of the year I will potentially travel to south west Florida, southern Wisconsin and Atlanta. Again no huge hurry. I would of course consider a unbroken pair if the deal was right. Thanks.

-

I ordered gold lion KT88s from Vivatube last week. I got them Tuesday.

-

interesting solution. I like the clean look of no fasteners visible from the front of the horn. I am assuming the extra holes on the driver mounting plate are for the fasteners that join it to the wooden portion?

-

Does the bottom of the speaker match the rest of the panels? If so, you can test oils and stains there and see what you like.

-

The deal on cherry is back on today for 24 hours on the 280f

-

Just keep checking. They seem to rotate the same deals very few weeks. I am waiting for a deal on a cherry rp-440c. Fingers crossed.

-

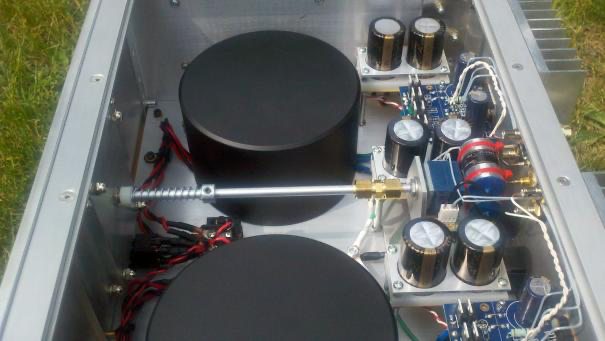

DIY Amplifiers - What have you built and is it a keeper?

No.4 replied to Curious_George's topic in Solid State

MyRef FE LM3886 based chip amp LM4780 based integrated chip amp-audio sector boards. KT88 SET - parks audio clementine board These are the amplifiers I have built over the last ten years. It blows mind how quickly that time went by. The first amp is actually the second shown. It is the LM4780 based audio sector amp. this is basically 2 LM3886 in one package. This was when I thought I needed lots of power. The second was the MyRef type amp. This is a great amp and I would definitely like to build another some day. It had noise issues that I could not resolve. The case is currently in process of becoming an F5 (or at least has been in process for 5 or more years!). The third is a KT88 clementine SET. This has been my daily driver for several years. This is a fantastic amp that powered my La Scala clones with ease and now powers the dual heil wave guide on top of the Scala clone bins. I would love to build many other versions of this amp but the boards are out of print. Someday I will build point to point. I have a 300B project that is also half done sitting on my desk. My original goal was to build a nice DIY hifi item at least every year. Seeing how long the KT88s have been in use, I may need to consider replacing them at some point. -

I have used the dap plastic wood filler under veneer with Great results. The Bondo wood filler is two part like the auto filler. I have not used it but I would like to try it. It probably sets up really hard and quick. I have used regular Bondo under veneer and paint on wood and it has worked well too. Just make sure whatever you use that it is set up and dry before you cover it.

.thumb.jpg.b17aa177a6f4e1497ac4340ed5725674.jpg)