erez

-

Posts

27 -

Joined

-

Last visited

Content Type

Forums

Events

Gallery

Posts posted by erez

-

-

thanks Marvel

today i try only SET amp, feel to me little bright, maybe its because i dont have autotransformer?

how much 'db' down do you recommend?

in bi-amp, i just balance with MIC.

-

-

build prototype of the DHA2. like @Marvel version.

I'm wondering if this is dangerous for the k55v mid?

the cutoff frequency is ~450hz and 6db/dec 😱

In any case, the sound is deep and with big soundstage

-

thanks

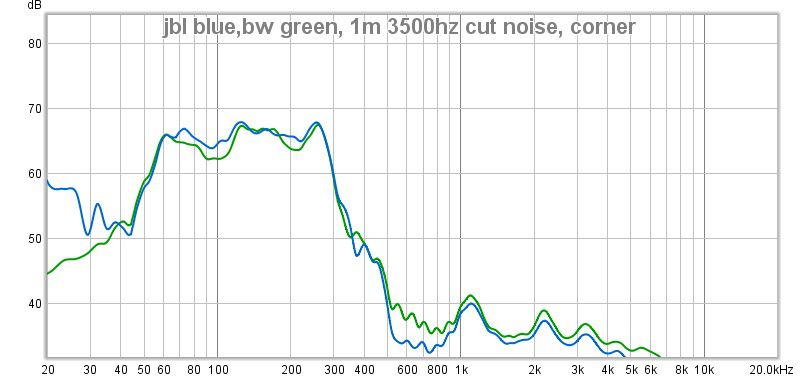

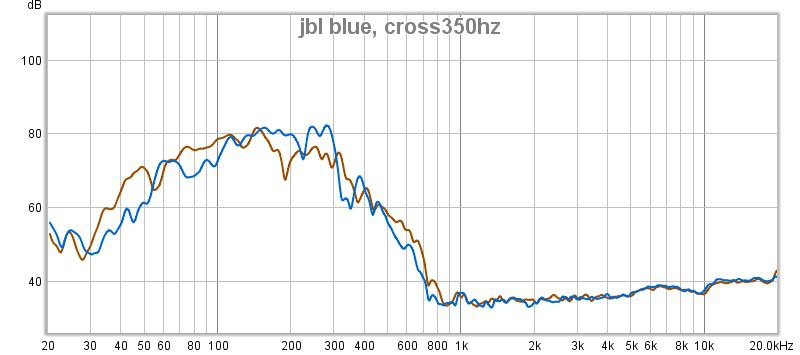

i continue with the JBL

-

-

-

-

-

-

-

-

hi

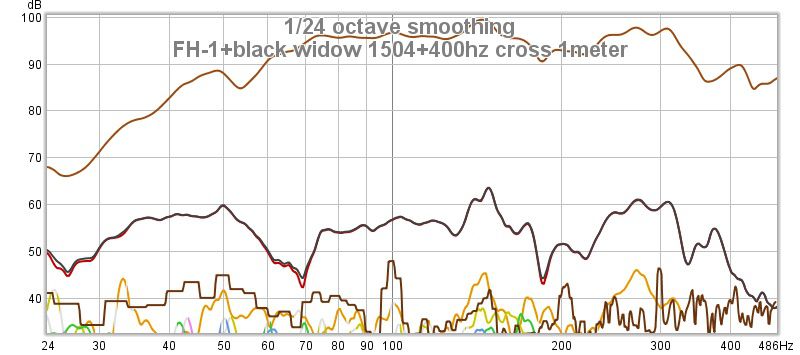

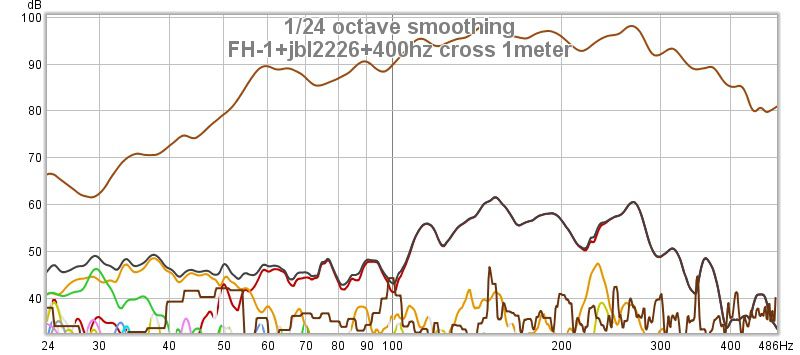

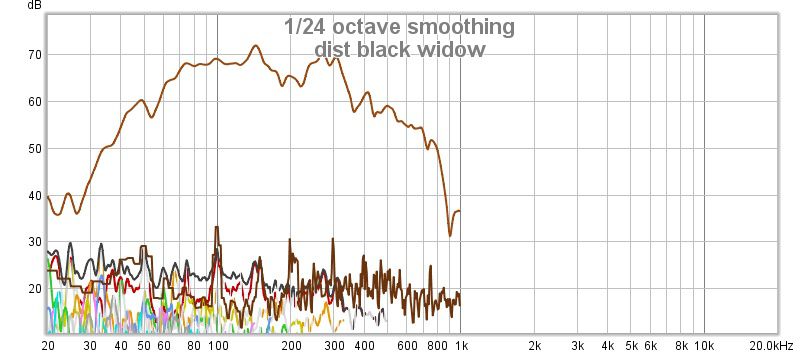

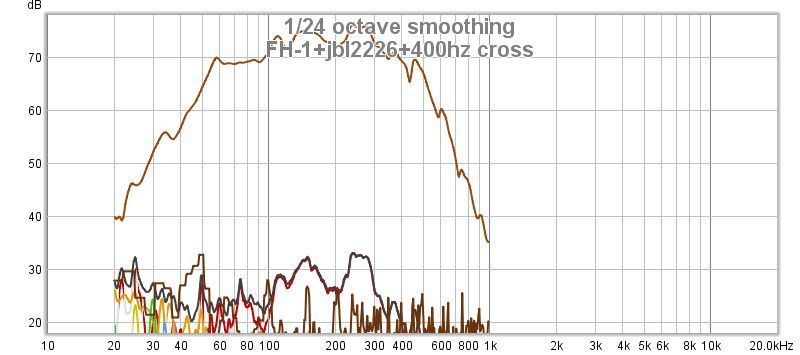

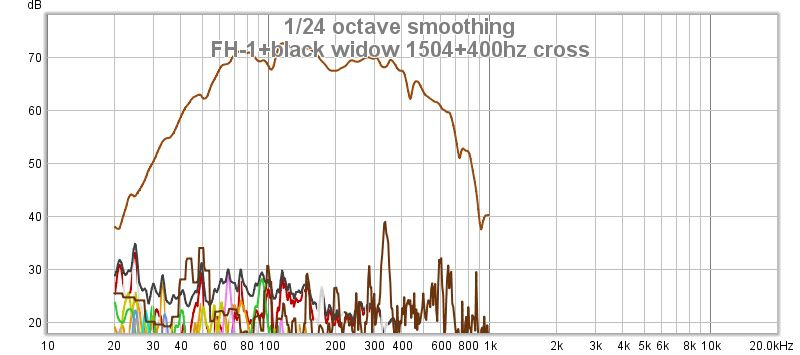

I have been looking for a folded horn for a long time, I almost built one, many thanks for @garyeanderson.and then I found the peavey fh-1. buy it for 400$. with new black widow 1504.

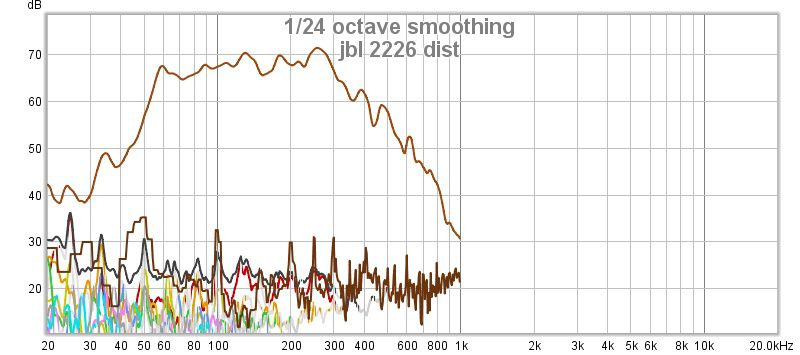

I understood from reading in the forum that the jbl2226 speaker is very high quality for folded horn, so i buy one, in addition to other forums they preferred it over the peavey black widow 1504.What do you think about the results?

the black widow 1504 is little more punchy

-

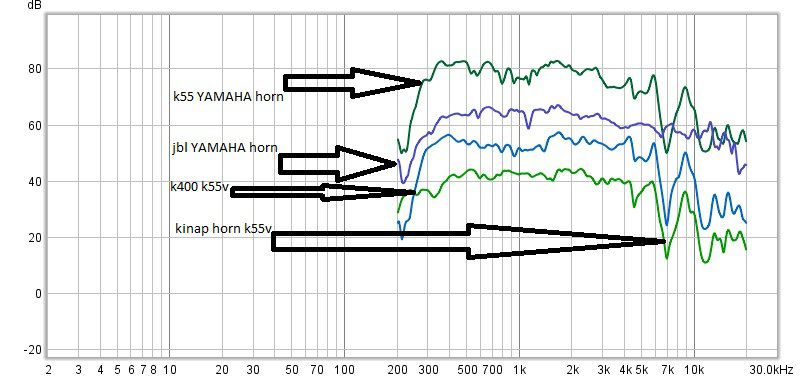

Recently I am interested in building SACLA speaker, I purchased and built some horn and speakers, below are the results:

K55v+YAMAHA H1230 horn

K55v+K400 DIY horn

K55v+LOMO KINAP horn

JBL 2447 +YAMAHA H1230 horn

with the JBL you almost don't need tweeter, but the titanium are noticeable.

the k55v little more flat to 3khz, the JBL more round curve

don't know what to decide. k55v or JBL2447. try the k55v with k77.

change the level for visualize.

-

Hi,

I'm trying to build the FH-1, does anything have a drawing?

thanks

-

-

If you have the schematics , I would be happy to get it

-

-

its jbl 2447 > adapter 1.5" to 1" > k400

of course the build its only for testing.

-

-

-

-

-

On 9/29/2002 at 1:05 AM, WMcD said:

It is not extremely difficult to build something similar to a K-400 out of wood. But it ain't easy, either. A photo of my first effort is attached.

My goal was to build a K-Horn without factory parts. So buying a real K-400 was not in my mind. (The bass horn was per the SpeakerLab plans.) Seems nutso, but such was my determination.

I'd be happy to correspond with anyone who wants to build the midrange.

The starting point was PWK's article about the K-400. That gave mouth dimensions and flare rate. That allows a calculation of area at any point.

Also, Dr. Bruce Edgar, in SpeakerBuilder, had described the technique of using flat pieces of plywood for the top and bottom surfaces for his tractrix midrange. He used a jig to hold the top and bottom pieces and constructed the sides with short lenghts of wood pieces, then filled them with puddy and sanded them. I call this the popcicle stick technique. I used that on another project.

Let me point out that the top, bottom, and sides of the K-400 follow an exponential curve, I think. Yet with Bruce's design, and mine, the top and bottom are linear. So the positions of the side walls have to be recaluculated to maintain an exponential area, in my case, or a tratrix, for his.

An issue in construction was whether I wanted to use Bruce's popcicle technique. Here, I used several layers of 1/8 inch plywood with yellow glue between the pieces. While the top and bottom pieces were on the jig, I pulled them into place with drywall screws (with washers) into the top and bottom pieces. You can see the puddy on the edges, covering the marks. There was a lot of triming necessary.

A more difficult woodworking issue arose from the fact that the driver I used had a 7/8 inch diameter. The Klipsch drivers are similar. That is an EV-1828 in the picture. Dr. Bruce didn't have to deal with it.

My solution was to use plywood down to an area of 1 square inch from the mouth. Then something different to mate to the driver. (Note, this is similar to the K-5 were PWK uses a cast metal mating device.) I made up donuts from plywood with hole saws and rasped out a flare. The ply donuts were difficult to work with. The driver thread, itself, was used as a tap to mate it.

This matching section was a bear and I didn't like the kludgy nature. In the second effort, I used three pieces of glued up 1 x 3 poplar to form a block, bored it with a 7/8 inch spade drill and rasped to mate with the 1 x 1 thoat of the plywood bell.

Also, Parts Express had a plastic device to mate the compression driver to a 1.4 inch diameter bolt on throat. So I adapated that to give a better screw on mount. (Sorry, no pictures just now.)

The assembly showed in the photos tested well. I can't say that it was worth the effort over buying a real K-400 or K-401. However, if you have the disease of, "I want to do it myself", it can be done.

Gil

hi,

just buy k55v and love to build k400 for them. do you have the k400 plans?

thanks

-

Last week I heard the la Scala horn, this is what caught me! The sound of the guitar coming out of the horn, I want one.

I just bought a k55v for 250$. And I was thinking what horn can I build for him?

and read about Bruce Edgar Tractrix horn

Am I in the right direction?

thnaks

curious about DHA2 crossovers

in Technical/Restorations

Posted

thanks for the help tigerwoodKhorns and JohnA.

my first setup is same DHA2 bi amp.

when i change to one amplifier, i here the brightness, so i thought its the bass power.

according to the mic measurement, the mid k55v is fall at ~5k, so change to 2uf is not good.

i try the L-pad