-

Posts

735 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Events

Gallery

Everything posted by MMurg

-

Repairing finish of La Scala AL5 Walnut Veneer

MMurg replied to ThomBoh's topic in 2-Channel Home Audio

I've been made a believer in Trade Secret scratch remover thanks to @OO1. Scroll down near the bottom on page 1 of this thread to see the before and after on the top panel from a 1981 Belle Klipsch. -

Yes, thanks for the suggestion. I got the big bottles because I wasn't sure how much it would take to do the speaker. I did the whole speaker, and it seems I hardly used any. The level only went down just past the neck of the bottle. I'm going to try this next on the 30-year-old Ikea pine table in my breakfast nook.

-

As I was applying the scratch remover, I noticed what appears to be a plug right about where the cover screw would come through. It looks like a previous owner made that same mistake on this Belle. LOL.

-

Thanks for the warning! I removed the cover already and didn't notice the different screw lengths. I just checked my set of screws. There are two cover screws that are shorter than the rest. Thanks to your warning, I figured out which cover holes are under the veneer. I'll be sure to mark those holes on the cover before I put the screws back in.

-

Another dumb question. Klipsch put a few small staples into the doghouse hatch gasket tape. Do you think I need to bother doing that? These are the smallest staples I have on hand.

-

I'm sure. However, I wanted to start with the lowest risk/hassle method first. If this stuff didn't work acceptably, that would probably be the next thing I would have tried.

-

Thanks everyone for all the help. I don't own an orbital sander, but with my hand sanding tool and a little elbow grease I was able to get the glue off. Now I finally have the Belle completely disassembled except for the woofer, which I don't need to remove for the finish treatment. Got all my fasteners organized in OCD fashion and numbered the grills left to right. Also marked the front of the hatch and riser in a hidden spot. The rest of the parts didn't need any marking to know how they go back together. I'll finish up the treatment tomorrow. Then I'll have to decide what I'm going to do about the machine screws with the inaccessible heads. 🙂 Thanks again.

-

Thanks. I don't own an orbital sander but I do have a sanding block and some paper. I'll give that a try.

-

I definitely needed to remove the bass bin hatch as two bass bin grill screws are under it. The problem was as suspected. The adhesive on the old gasket became soft and runny and glued the hatch shut. A wood chisel, hammer, and some gentle tapping/prying allowed me to get under it and pry it. Luckily, I happen to have some peel and stick speaker gasket stripping from a previous VMPS subwoofer passive radiator repair that looks to be the same size as the stuff I scraped off. My only issue now is what to do about the old glue still stuck to the hatch door. I scraped off as much as I could with a putty knife. Normally, I'd try Goo Gone or something similar, but I don't want that soaking into the bare wood. Short of making a new hatch door, what are my options? Can I just put the new gasket over the old glue since it will be held in place by the hatch?

-

I tried some of the Trade Secret scratch remover on a few pieces so far. I decided to try the light color one first as the speaker finish is really a medium color. I'm very pleased with the results so far. Here are before and after shots of the top board. I'll reevaluate after letting it dry a while and see if I need another coat.

-

If the threads ever get messed up, having permanently epoxied screws might end up being a nightmare.

-

@HDBRbuilder - Any suggestions on how to tighten the machine screws/bolts that hold the Belle Klipsch top hat side panels to the top hat bottom board? There is no access to the head of the machine screw heads once you put the bottom board in place and screw in the screw that goes under each of the side panels.

-

I was thinking about maybe putting threaded inserts into the bottom board where the through holes are now. This is an older Belle made of lumber core panels. So, it should hold threaded inserts well. Then I could just use pan head machine screws from above.

-

I don't understand the fastener choice here. The top board of the top hat is connected to top flange of the side panel with wood screws that are screwed directly into the top board. However, for the same connection with the bottom board they used flat head machine screws and nuts. Also, it's in a place where you have no access to the screw head when you have to tighten it. I don't get it.

-

Success on the nuts holding the side panels! Thanks! After loosening both so they were spinning, I pulled up on the side panel to put the bolt in tension and used a socket to get it to move up a small amount. Once that was done, I pulled up, pressed the putty knife against the bolt underneath the panel, and was able to use the socket to remove it the rest of the way. Once the panel was off, that exposed an additional screw holding the bottom panel of the top hat down. I'll do the other side panel tomorrow. Now I have to figure out how I'm going to retighten those bolts when I put the speaker back together. I wonder if the tension trick will work for tightening.

-

There is no access to the head of the bolt that I can see. It either goes just inside the collar or through the collar. I hope it's not something evil like it goes all the way through the top of the bass bin. Looking at Belle drawings I found on the Forum, that would put the bolt head inside the bass horn behind the grills. That would be some great Catch-22 situation as I think the grills are screwed in from the top (under the top hat) and the bottom.

-

Hi All, I'm trying to disassemble a Belle Klipsch so that I can get the grills out. I want to try a scratch cover treatment on the places where the lacquer is messed up and I didn't want to get it on the grills. I also figured the least conspicuous place to try it was the inside bottom of the top hat. I removed the motorboard/grill/driver assembly and the crossover without issue. I removed the six screws along the front and back inside edges of the bottom of the top hat (green box showing where one was in the picture). I thought that would free the top hat, but it won't budge. I tried loosening one of the nuts on the bolts holding the top hat sides on (red box), but now it just spins because I have no way of grabbing the head of the bolt. Am I missing something? Do I need to get these nuts off as well? If so, how do I do that when I have no access to the bolt head? Another issue I have is with the hatch on the bottom that I assume gives you access to the woofer inside the doghouse. I removed all the screws, but it won't budge either. Should it just come off once the screws are out? I feel a little something sticky along one edge. Is there a foam seal for the doghouse hatch? Is it possible that degraded and is acting like an adhesive? Any suggestions? Thanks.

-

Yeah, since the Jubilee were setup I have questioned the wisdom of doing this center speaker. 🙂 However, I had already purchased the speaker and everything else I need to convert it to two-way with an Axi2050 HF. So, at least I will try it out once Parts Express finally gets the Axi2050 back in stock.

-

Yes, that and a different tweeter. That stock tweeter just doesn't have sufficient top end extension for me. However, neither will matter once the Axi2050 arrives. 🙂

-

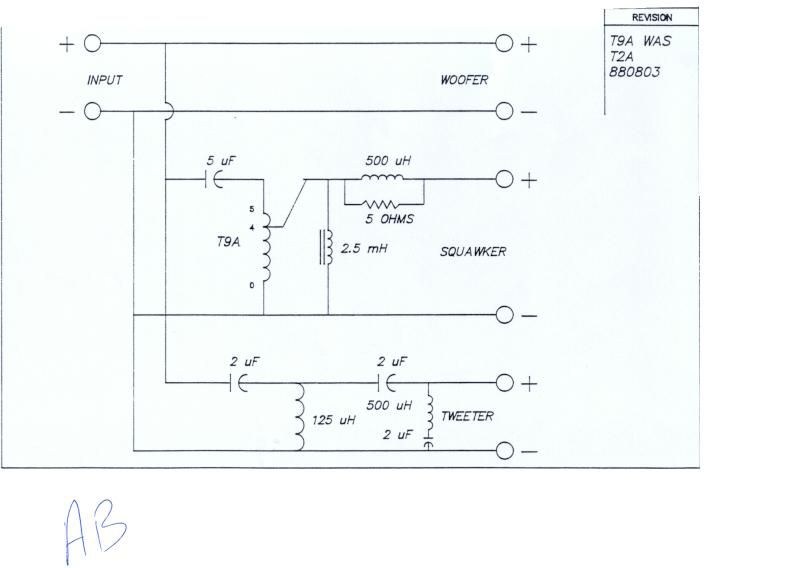

So, I finally got around to hooking up the stock Belle Klipsch center temporarily just to see how it sounds this way in the Jubilee setup. I wanted to do it as a passive bi-amp to test the amp setup for the later two-way conversion. I just used a balanced Y-cable to hook up to the amp for now. I looked at the AB crossover schematic. It looks like just disconnecting the woofer and wiring it directly to the amp is all that needs to be done for passive bi-amp with this crossover. So, that's what I did. If I've misread this, please let me know. Unfortunately, in the stock configuration it's not a great match for the Jubilee. I tried one of my favorite multichannel music tests for this, Annie Lennox singing Into The West during the end credits of Lord of the Rings: Return of the King Extended Edition. In my all-Palladium theater system, she sounds heavenly. Her voice has an almost bell-like quality. I get goosebumps every time I listen to it. However, on the Belle she sounded flat and a little shouty. The magic was gone. I'm sure it will be better once this speaker is turned into a two-way with the Axi2050. One interesting thing I hadn't taken notice of on the back of the speaker was the sticker in the last picture. Apparently, this speaker is the survivor of some disaster in Utah. 🙂

-

Just the usual speaker distance function in the processor.

-

Ok, then how about this to get things back to speakers. This past Friday I made a 9-hour + round trip in a Uhaul van to get a pair of used La Scala AL5 in cherry. These will be used as surround speakers in my Jubilee room. Now the 5.0 setup has fully horn-loaded speakers for all channels. The seller lives right on the shore of Lake Ontario. They have a spectacular view from their backyard.

-

I was the one who asked about it for my Belle center.

-

I was going to try parkour between the speakers and the rest of the furniture while playing "the floor is lava". 😁

-

Yes, I saw their marketing text. I was hoping you might have some real world experience as to whether that statement is actually true or not. 🙂

Markedup.thumb.jpg.e15d9fa12c1aa21914c34a2aa9a61995.jpg)

.thumb.jpg.773e79c2cc56b805c02401b1afdd7c31.jpg)

.thumb.jpg.49dba9456b9193384d2b7cd9938126b4.jpg)

.thumb.jpg.dbf7205ab71525042391ba31445c0b7d.jpg)

.thumb.jpg.470b3c1b0a3d2f891b5fe8c5942635d6.jpg)

.thumb.jpg.148e51cbf412af76b702bfb87daaa3b7.jpg)

.thumb.jpg.cb4e15cd41265f5278992fcc1d59330d.jpg)

.thumb.jpg.70cd4c51f20327d009ed05e224065ca4.jpg)

Markedup.thumb.jpg.60703ca909997cd8bd96436fda1f2a6b.jpg)

.thumb.jpg.28217661f71e156d703e86612606541b.jpg)

.thumb.jpg.3db3b19efaa0e9670f8096da2452e72d.jpg)

.thumb.jpg.9cd13fe916fb4610fdb5b7a5491e4b0b.jpg)

.thumb.jpg.95649a2285b278eb0225f9162f298554.jpg)

.thumb.jpg.4455864f527e72be22a35d17a9d5702c.jpg)