-

Posts

1115 -

Joined

-

Last visited

Content Type

Forums

Events

Gallery

Everything posted by vasubandu

-

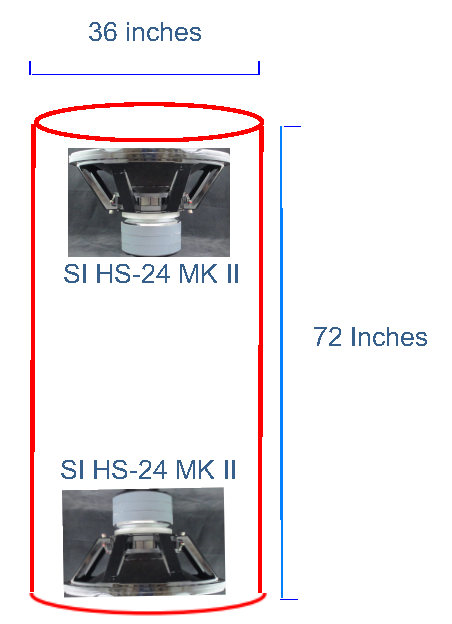

Thanks, That is a good point. I am going to guess that box is 4x2x2, or 16 cubic feet before driver space. In a ported sub the SI HS-24 is rated for 16 to 20 cubic feet, so with 2 of them 32 to 40. Even with large ports, I don't see how it works. Of course, they know a lot more about it than I do, so I am not saying that I am right. I am just thinking and wondering if they would work better with twice the volume.

-

I can easily join the plywood with a seal of equivalent strength. The idea that a cardboard tube would be stronger than a tube made of 5/8 inch plywood seems dubious to me. Sheer walls are made of plywood, not cardboard. I want easy access because I want to be able to change the location of the drivers. The idea of moving a 115 pound driver through a 36 inch access point does not sound like fun. I am being helped by a contractor friend who is a magician with wood, and he says this will be a few hours on a Saturday afternoon. Part of this is just that I have always envisioned it as a substantial wooden structure.

-

That was my original thought, but since I have to join the parts of the tube and since they are not precise sizes, I thought that getting them made since so that I could make physical measurements instead of using hypothetical dimensions., I certainly would not buy any other parts until it was all planned and designed. With the tube I am going ot get what I get, and I won't be able to change it.

-

It would. I think it was Jesus who said “Watch and pray, that ye enter not into temptation: the spirit indeed is willing, but the flesh is weak.” On the positive side, I have been considering making a 24 inch tube at the same time or even first. That would be smaller if not technically small. You cannot imagine how frustrated my wife gets, but she says she loves me anyway.

-

In case anyone is following, I have resolved the questions about the enclosure and will order pieces for a 5/8 inch curved plywood tube 36 inches in diameter and six feet long this coming week. They offer full circle, half circle and quarter. The pieces normally are 36 inches long so I will need to join them. My plan is to get 2 half circles and 4 quarters and then permanently join one of the quarters, leaving a quarter opening. I will use the remaining pieces to make a removable door that is sealed when in place. That way I can get into it to work on it. The wood will cost $400. The door equipment will cost a few hundred more I am guessing. I am assuming that I want it air tight, but not sure on that. I am getting the HS-24 Mk II drivers from SI and Nick there has been really helpful. He actually seems to want to see what will happen. SO I contacted him about amplifiers, and he just said to use speakerpower.net. If it works for him, it works for me, and they have a 4000W plate amp with 2 channels for $999. That should power both drivers perfectly and is cheaper than I had feared. So it seems that parts have all been decided and I should have them by end of April. And that leaves getting serious about learning design. So if you don't see me much for a while, I am in the library.

-

It is a very specific kind of precook. You cook the food in a sealed (preferably with all air sucked out) bag at very low temperatures for a very long time. We are talking 120-130 degrees. That very gently coos the meat through to the desired doneness which can be rare if you want. And then it is finished on a very hot grill to create the texture and appearance you want. I learned about this from an amazing meat store in the neighborhood, and at first I thought the guy was making it all up because they are very very serious about their meat. But he said that no matter how good you are with the grill, you are still cooking the inside that you can't see, and if you lose count of how many beers you have had, you probably will lose track of time too. The thing I notice is that the meat has no toughness, even on the surface. I had not realized before how much the texture around the surface is affected. If you want to try this, there are lots of sites online that explain how to do it with a pan of water, a thermometer and a timer. It works for your wife. Maybe you would like it too. We won't tell anyone.

-

Hey, wait just a second, you are in southern Californa. It is in southern California. Just but the KV-4 for $200 and the send the CF-2 up to me. Actually, I would not be after them, but with a deal like that, flip and save. P.S. I know San Francisco is not really southern California, but I would never let a technicality get in the way of of a good story.

-

That is a pretty good deal.

-

Have you ever tried the sous vide method? I use it for steak, hot, warm, or freezing (which in Seattle is anything under 50 degrees). http://www.seriouseats.com/2015/06/food-lab-complete-guide-to-sous-vide-steak.html

-

Thanks, all of that was helpful. I figured that the port size would dictated by the rest of the the design in the end. I have even thought about looking into leaving both ends open in an open baffle kind of way, but that was just an idle thought. For stability, I have considered high density concrete at the base, and I have also wondered if it would be feasible to suspend it from the ceiling. If the connection were some kind of textile,, it might not transmit vibrations. I have no idea what that would do, but it would achieve close to complete isolation. As I understand it, opposing drivers are usually wired in phase. I know there are wave cancellation issues, but have not gotten that far yet. Will reach out to you directly.

-

Thanks so much @PrestonTom I am using the Sonotube software along with WinISD, but having problems with the latter. I am looking for any other software worth using as well . Trying to figure out Unibox and looking at others but hard to which are worth the cost or worth using. I have always planned it as ported, but am not quite sure why. The drivers I have looked at seem to need a lot less space enclosed than ported, but I am basically trying to what happens if a lot more volume can be efficiently used. As for how lot it needs to go, I tried listening to tons on YouTube at everything from 15 Hz to 30 Hz. We have FireTV, so I did that on the home theater system. Even at 30 Hz, I really don't hear anything, At 20 and below, I heard nothing, but felt vibrations and things i the room shook. This is not about going really low, so maybe 18 Hz or so. If it goes lower great, but that is not the point of the project. I did have a goal of seeing is these super subwoofers that some people are making now can actually be used for home theater. It seems that in theory a 24 inch driver should be a lot of fun if made well, but I don't see how they get into a traditional box. And if it were truly possible to use 2 24-inch drivers in the space of a 36-inch circle, I suspect a lot of people would find the room. Maybe I am dead wrong. Happens all the time.

-

SOLD: Klipsch CF-3 v3 Medium Oak - Pictures added

vasubandu replied to avguytx's topic in Garage Sale

Wow, those are gorgeous. I am never posting another picture of my speakers. -

I actually do try to figure it out and I have been looking for subwoofer advice in AVS, which has a totally different system. If I put something in the wrongplace or dosomething else wrong, mods are free to just delete it. I will not take offense and i won't complain.

-

Seriously thinking about this and wondering why I am wrong

vasubandu replied to vasubandu's topic in Subwoofers

Hey @JBCODD I cannot possibly thank you enough for this. It is the kind of information that I am looking for. Very different approach in some respects, but maybe better. Thanks. -

Seriously thinking about this and wondering why I am wrong

vasubandu replied to vasubandu's topic in Subwoofers

Fair enough. I have thought that the different threads were different enough that asking the new question in the old thread would be dissonant. I guess there is a balance that I struck the wrong way. I also thought that when I finally began the actual process of building it, a build thread mad sense and should replace anything else. Maybe I just don't get the Klipsch way. -

Seriously thinking about this and wondering why I am wrong

vasubandu replied to vasubandu's topic in Subwoofers

Thanks. Something is weird with my version of WinISD. I don't get the usual interface. I have contacted them for help. In the meantime, your statements and explanations make a lot of sense. On the one hand it seems like if bigger ports were needed, they could just be made bigger, but I get the feeling that I am going to learn it is not that easy. Your help has really been valuable. -

@jimjimbo keeps saying this belongs elsewhere, but I don't think I can move it. Can a mod do that?

-

@jimjimbo

-

Thanks @PrestonTom I really appreciate the comments. For background, I would call this a proof of concept, which kind of funny because as little as I know, one could say that I should get a clue before I start having concepts. But that whole walk before you run never made sense to me. Thanks for the thoughts on 24 being too much. This could be scaled down to 18 or 15, but then I wonder about space. As I said in my post, Nick at SI was so generous with his time and thoughts, and expressed enough interest in the outcome that I would get whatever it is from him. Their HST-15 MK II has a 108 Vas, which is 3.8 cubic feet. For reasons I am too embarrassed to admit, I am doubling Vas for my considerations, so that is 7.6 cubic feet per driver or 15.2 for the system. An 22 inch interior tube six feet long would have a volume of 15.8 cubic feet. With components, it would be a bit short, but that ought to work. It also might improve the WAF. My questions in this are twofold. First, I want to see if subwoofers can effectively be made bigger by going vertical. I think that vertical expansion would be more acceptable to people than horizontal. Second, I am curious to see if we are choking our subwoofers. To give you an idea, the SI HS-24 site says 16-20 cubic feet for a ported enclosure. 16 cubic feet is a box 2.5 feet per side. Stick two in there and it is 3.1 feet per side. Nick told me that he did not of any instance where people actually provided it. I have some idea what the modeling says, but I am not entirely convinced that modeling equals perceived sound quality. And if this works, I wanted it to be something completely different. I am not sure that two 15 inch drivers could do that. But 2 24-inch drivers might if they worked better. I know that separate boxes would be better, but that would just get me two good subwoofers, not answer my question. It is hard to explain, but I really don't even care that much if this works or not. I just want to find out. So design choices are made to answer that question more clearly or decisively rather than by what makes the most sense for my home theater. Your experience with the sonotube would really interest me if you cared to share it sometime. You are the second 6-footer I have encountered, although I am sure there are more. It sounds like you had only one driver and it sounds like it worked out. Any, way really do appreciate your thoughts. You have me reconsidering many things, and that is always helpful.

-

Well, the next time you cook up 350 pounds of crawfish, let me know, and I make a road trip. It would take a while, but you could not possible eat 350 pounds before I got there. I have never had a crawfish, but I bet yours are to die for, and I would love to try them. I don't use any prepared mixes for salmon either. Local food made by local people always the best.

-

I hope this is the right place. Did not see a separate DIY place. I am going to get started on my subwoofer. By started, I don't mean putting things together, but I will start locating and parts and getting them so that I can be sure that the next parts will work. The final product should look something like this A lot of people said to use a sonotube, and I guess that is what most people do with round subs, but it seemed inadequate for a six foot subwoofer with a 115 pound subwoofer at the top. And after searching to the ends of the earth, I found that that a simple, readily affordable alternative exists and is widely available. Bent plywood. It is strong and will not resonate because it not a sold product. It could be made with a full circle or two half rounds that were joined later. I am leaning towards the half rounds because it would make installation easy and the joint would be covered by veneer anyway. If made with 4 pieces (36 diameter by 36 long), it would cost $400. That is a lot more than Sonotube, but it is 5/8 inch plywood. After a conversation with Nick at Stereo Integrity, I decided to to use his 24 inch driver. It seems like a quality product, and if nothing else he expressed more interest in my project than just about anyone else. Now I need to deal with the amplifiers. They are rated at 2000 watts apiece, and I have no idea how to make that happen. I have not found a plate with that size amp. And so it goes. Hoping to finish this by end of April.

-

Hey @T2K Is that a Maine Coon? Sweet looking cat.

-

And for the record, I would never teach a coonass how to boil a crawfish. I get the prepared crawfish that don't need to be boiled. Too much hassle to boil them and they taste the same.

-

Coffee now? We are enjoying a nice bottle of Stag's Leap Petite Sirah. I'll need the coffee in the morning, but it can wait.

-

Seriously thinking about this and wondering why I am wrong

vasubandu replied to vasubandu's topic in Subwoofers

And I think that I may have stumbled across another part of the puzzle. Why have cardboard when I could have wood (need to look at issues)? Just 40 miles away is a business that specializes in bending wood. Maybe two plywood halves and join them. But for these guys, that would be a walk in the park. Their stuff is amazing. http://www.puretimber.com/architectural/