-

Posts

5463 -

Joined

-

Last visited

-

Days Won

12

Content Type

Forums

Events

Gallery

Posts posted by jason str

-

-

No room for tunes in the garage or workshop ?

Gifts for the family ?

Make some new cabinets for a project ?

For that price i could find a use.[

]

] -

Went out yesterday to grab some lunch at El Famous Burrito, yeah the football sized one i like smothered in the spicy red sauce and there in the corners blaring mexican music i could not understand were what looked like a couple of KG1's or 1.5's. Nice sounds from some tiny bookshelf speakers though the music was not my style.

-

$525 is on the cheap for a set of Chorus II's, these should go fast,

-

I used a similar technique on my La Scala midrange exponential horn and it did tame some of the harshness.

I went with the spray from parts express.

-

I was just blown away my how good the Chorus sounded and would have bought them instead if my wife hadn't stepped in.

NEVER take the wife shopping for audio equipment, you may never be happy with the outcome.

Wait until they leave or you will be stuck with what looks good to them instead of what sounds good to you.

If they don't get it mention next time a major appliance goes on the fritz like her stove or something similar tell her the old one is too big and 2 burners is enough to cook on anyways right ?

Maybe thats why I'm divorced.[:#]

-

Chorus II's won me over after months of shopping around for speakers, never looked back.

-

I'm not sure what sends me to the crapper first, its a toss up between mickeydee's and Taco bell.

Pickles on pork ?

I meant pork like processed meat substitute on a sesame seed bun.

-

Bob can hook you up with some wire. http://www.critesspeakers.com/

Or run over to radio shack and pick up some 16 gauge or better, been using it forever with good results.

-

That cardboard roll really helps when you are out of paper and in a pinch (no pun intended).

-

Still using my old Grado SR 80's i have had for some time now with no complaints, very nice sounding cans for a reasonable price.

Previously i ran with a set of those kinda heavy old green Koss sets but they fell apart after many, many years of use, i don't miss em at all, they made my ears sweat too much and were not very comfey.

-

Thanks Peter, good to know, now all I have to decide is to make 2 Tuba HT's with the Eminence Lab 12's or buy 2 Dayton 15" drivers and make the wider cabs...

I really want great low frequency extension as well as decent SPL's

Using 2 smaller Tuba HT builds and worrying about not having enough output should not be a concern, i would use the 12" drivers you already have on hand.

There is a chart somewhere using the LAB 12 in the Tuba HT, i will try to find it and post a link for you.

-

After the PL dries and expands to approx. 1/16" per side of your brace you should be perfect.Here's a tip for THT builders... I cut the first braces at the specified sizes but they turned outnot to be tall enough by a tad over 1/8". Here's a pic of the gap. I pused in the two side braces a little deeper in, and added little pieces of wood to the middle one that overlaps the driver for it to fit there. The next braces I measured in place prior to cutting to size to get an exact fit.

-

The Google SketchUp plan showsthe panels flush against the access hole. I think I'm okay. BFM doesn't think such an error would make a big difference in the sound.

There should not be any difference in sound, however that can be a weak point. Make sure you glue the snot out of the access door mounting you will be installing and be sure its square as this cannot have any air leals.

Once the first few panels are done the rest is just repetition, don't forget we are here if any questions arise.

-

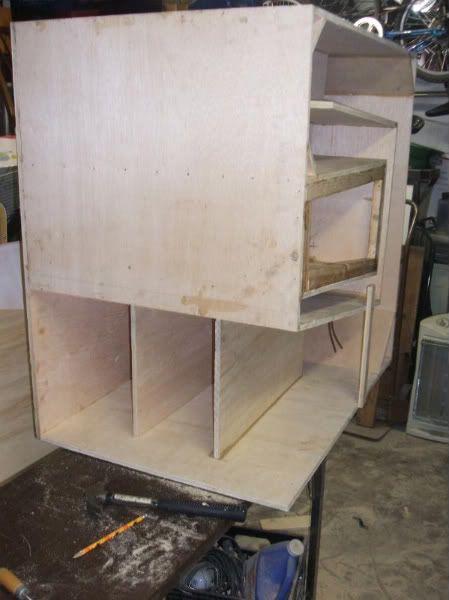

Here is mine, notice i cut my access hole after most was done. [

]

]Braces are glued on 2 sides once the side panel is installed.

-

Page #11 shows a better view of the inside after panel install.

I see the same was done on the other build, the overlap of the plywood will allow glue on 2 sides of your side access panel braces insted of one.

What i was going to recommend is ripping down some 1/2" plywood and glue down 2 overlapping layers making 1" total.

-

Overlap? Panel 2 is mounted flush with the access hole, isn't it?No, you should have left a 1/2" overlap on panels 2,3, & 4

Panel 1 should be 1" overlap, there is a large detailed picture in the plans on page 6 of 23 (pdf version).

-

View from the other side. Apart from that, I cut the two angled edges into my baffle panel and brought it home. I will cut the circle this week at home to save time at the next class. I am measuring 13 7/8" for the recommended Dayton driver. Does that sound right? (It's certainly smaller than 15"!)

Thats just how it is with driver sizes, has not changed as long as i can remember.

Did you leave the 1/2" overlap for the driver access hole ?

Maybe its just my poor eyesight.

I may have a fix for you if this is the case.

-

Looking good, i like the fact that you did not overdue it with screws witch tends to weaken the structure due to splitting your panels in two.

The finishing is the hardest part if you are picky with the outcome, propper prep is a must for a decent finish.

Keep the pictures coming.

-

Good time tonight, lots of tunes and friendly faces.

Pro Cornwall's & Chorus II's W-mods and lots of other goodies listened to tonight, lots of alcohol & stuff to keep my mind off the new gaping hole in my gums where my biggest molar once stood proudly.

Maybe a used set of Heresy's to play with if all goes well too (like i really need more stuff right).

Hope to see everybody again soon. [Y]

-

Do you think they will also release it on a cassette tape?

8 track only. [+o(]

Wonder if i still have my old Pioneer supertuner with the round dial complete with fancy 8 track player, i cant tell you how many dash boards were cut up to install that bad boy.

-

jason, the driver enclosure, or doghouse as it's often called here (after all, it's where the woofer lives), has no issues with rigidity or resonance. The only "problem" area (and it's not a problem to many LS owners) is the large side panels that are secured on only three sides, and on those sides, the supported edges are two feet apart.

The back is secured on four sides, plus it has the chevrons attached to its inner side, which also attach it to the doghouse, so it's secured in the middle as well. Those chevrons are the beginning of the bass horn. Meanwhile, the doghouse is smaller and is secured on all sides. It's pretty solid.

As for the bass horn, adding anything to its insides will change its engineered dimensions, changing the sound in the process. Besides, wood is not like metal. It has a much higher damping factor by its nature. Wood doesn't ring, which is why it's never used to make bells.Makes sense, my idea was to mainly hide the glue that will be needed for the braces and i figured it would not hurt to do the whole thing.

Wood does not ring but it does have its own tone.

Good news on the back of the cabinet, i was wondering how much support was back there.

-

I've put an old 5 pound soft dive weight on the 400's before (soft weight = the small bag with the lead shot). Never had any problems with the 401's, but I have also isolated them with a rubber gasket on the face and a rubber washer on the vertical metal support at the back.

Did you also use rubber grommets to insulate the screws from the horn ? Otherwise all your insulating may not be useful.

-

Bummer Colter....maybe next time.

There's still plenty of room if any late stragglers wanna swing by for a bit...

I better get back to fixing my computer....my main laptop I use for playing music just crapped out, so I've gotta go to plan B

We will be over around 7:00, Gary had to work until 5:00 and is headed right over to pick me up rather than taking 2 cars.

If you need help with your computer i will be happy to have a look, see you soon.

-

I think that damping some slight vibration/resonance on the mid horn is different from trying to stiffen a sheet of plywood, like the sides of the LS bass bin. That needs mechanical stiffening, like adding braces or adding a layer of plywood on the outside. I don't think the spray would be much help in that application.

Yes, brace first then some damping spray was the plan.

Nothing is planned for the outside of the cabinet, my plan was to install the braces, remove the driver and go to town with the damping spray on the driver enclosure and inside of the bass bin & maybe the back of the cabinet if i can't find my big roll of self stick damping material.

Whats your preference---Compact Disk or Vinyl Record

in General Klipsch Info

Posted

I like the convenience of throwing 5 CD's into my CD player but i prefer the sound of vinyl, whats your opinion?