-

Posts

984 -

Joined

-

Last visited

Content Type

Forums

Events

Gallery

Posts posted by Blvdre

-

-

9 minutes ago, OO1 said:

He purchased a set of Alnico K-77 last Friday

Eh, they'll probably be fine.

-

On 11/9/2023 at 2:56 AM, OO1 said:

nope , the specs sheets for the late 70's T-35 Alnico and T-35A Mud , show identical Frequency characteristics and Output sound pressure levels - 3.5 kHz to 15 kHz ± 3 dB / 104dB W/m

https://audio-database.com/ELECTRO-VOICE/unit/t35.html

.https://mypicsonline.net/archive/archives.telex.com/archives/EV/Horns/EDS/T35A EDS.pdf

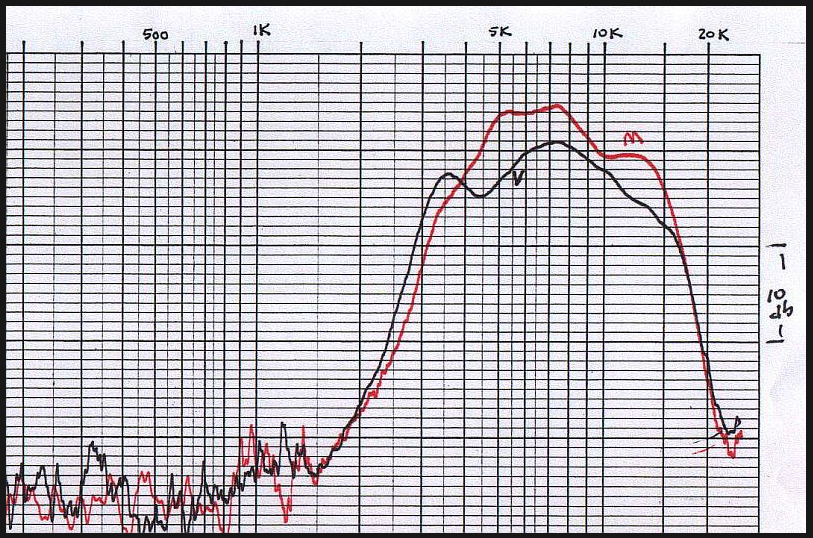

I was recalling Al's plot of the K-77M (red) vs the Alnico (black), but to be fair, the Alnico magnets may not have been up to snuff. Given that issue being a possibility when buying used, though, I'd still recommend the K-77M for Erivera.

-

6 hours ago, Erivera1990 said:

For what I read, and correct me if wrong. K77 round magnet is the older version and the K77M square magnet is the newer-ish version? My klipschorns are from 1990, not sure if I would hear any difference between the square or round K77?

Also, what's a fair price for a pair of K77M tweeters? Seen a few on eBay but I feel their prices are too high.

You are correct, the K77M has the ceramic magnet, and it's response differs from the older alnico tweeters. You are on the right track looking for a k77M replacement, to preserve the proper voicing of your Khorns.

-

2

2

-

-

5 minutes ago, OO1 said:

there's a used set of RF-7 II on Ebay for 1300$ , that's a smoking deal for such a HQ pair of speakers

That's a great deal. Wish I lived nearby.

-

On 9/21/2023 at 1:59 AM, OO1 said:

ou're better off seeking the RF7 III which are 1 step up from the RP-8000F II , some dealers discount new demo units with a full warranty

Even with a discount, that's a very big price discrepancy.

-

1

1

-

-

PM sent.

-

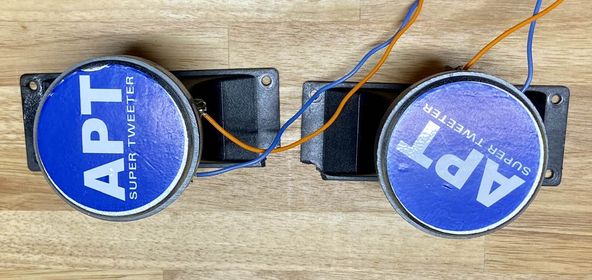

I have an early pair of Crites ct-125s. The bad, a couple of broken mounts (1 each). I need a torque wrench. They mount fine as-is. I bought a replacement horn from Bob (when I only needed one replacement), but never got around to replacing it. The finish is different, shinier.

The good: Like I said, they mount up fine, and work perfectly. $100 plus ship.

-

It sounds like the input selector switch is bad. The sound you describe is what a turntable plugged into a line-level input would sound like. Turntables require RIAA equalization for proper tonal balance. Without it, your phono will be all treble, no bass. Just a guess, but I think the switch isn't changing the input from line to phono, so the line level input is always selected.

-

1

1

-

-

There's probably a metallic bit(s) that stuck to the magnet in the gap, causing the voice coil to rub against it. I doubt that the voice coil is out of alignment. Unfortunately, you'll have to remove the cone to clean the gap out. This will probably entail having to replace the surround.

-

PM sent

-

If the speed is varying while playing (audibly slowing down), the pot's wiper or resistive element may be dirty. In MM's posted instructions above, I would add step 1.5: Run the adjustment for both 33 and 45 rpm back and forth, from end to end, several times. This will help clean the wiper and resistive track of dirt. Many potentiometers don't have a hard stop at the end of their adjustment, but will make a quiet click, so keep your ears open.

-

2

2

-

-

Fast or slow-blow?

-

1 hour ago, Crankysoldermeister said:

I do NOT "sling" solder, lol.

Crankysolderblobmeister.

-

-

Glass. It might be best to just be patient and measure once they've arrived. Tolerance stack ups can cause slight variations within the same model group of any product.

-

3

3

-

-

11 hours ago, rigma said:

This tool works great for deburring these holes. https://www.amazon.com/gp/product/B001O5YSXU/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

I can vouch for this, as well. I've reamed out many a vintage cymbal mounting hole from the old 7/16" to the new 1/2". This demurring tool works well to break the sharps.

-

I will, too, if I can ever get the remaining cables built out. $5.00 is a bargain.

-

I have several interconnects using this. Good stuff, studio standard.

-

If the old gear hasn't been serviced, be prepared to spend some money getting it up to snuff, if not right away, then at least eventually. Electrolytics dry up, switches and pots get worn/dirty. I've repaired a few pieces, and while it's rewarding, it's a commitment of time. 100% worth it to get it back to spec, though, if it's something you want to use/keep for the long term.

-

1

1

-

-

12 hours ago, Crankysoldermeister said:

Sure. Make sure you wear safety glasses while doing it.

Years ago, when I worked on the bench repairing electronics, I was soldering together two wires that didn't have a good mechanical connection (my fault) and one of the wires popped off and splashed flux in my eye (wasn't wearing my glasses). Luckily, I had contact lenses in. Ruined the lens, but saved my eye. Always wear your safety glasses when soldering.

-

The pic is unclear. The Vinyl cap could be just a slip-on cover, or have a central threaded post that screws into the insert. Since they call it a cap, I'm guessing the former.

-

Pdow, McMaster-Carr may have what you're looking for, if you can figure out the thread size/pitch. The threaded posts that remain could have been the threaded post molded into the rubber foot of the speaker. What does the receiver look like? You may be able to remove the post by just unscrewing it, and using a new foot with an integrated threaded post. If the post doesn't want to budge, look for a foot with the correct receiver that will screw onto the post.

-

Mike's right. It's SOP for manufacturers to keep a stock of repair parts for post-production products, usually with a policy of support for X number of years. Our company does it for a service period of 10 years (laboratory test equipment), but it could be more or less, depending on the technology and period of relevancy.

-

Cornwall I restoration

in Technical/Restorations

Posted

Who exactly are these private vendors? Both Deang and JEM Performance are approved Klipsch service providers. Deang offered good advice regarding ESR testing of capacitors, and was providing sound direction for the OP. I don't see anything to criticize here, except that fewer and fewer truly knowledgeable people are left on this forum.