-

Posts

4761 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Events

Gallery

Everything posted by Dave A

-

The harder you push them reminds me of an episode here. I had some Nashville musician types show up one day to look at some EAW speakers. Have to admit they boasted of 132spl but sounded like crap. So I show them to these guys and they ask me "what is that over there"? Against the wall was a set of KP-301-1's I had reworked and they were not for sale. So I said "not for sale is what they are". Well they kept whining until I said "OK I will fire them up for you but they are not for sale". So I plug them up and they want to know how loud they would get. My Crown amp has 200 wpc and the speakers are rated at 200 watts per so I thought OK lets just see what they do. I can always fix them if I blow them up. So I get my hearing protection on and crank them up all the way. They got these goofy grins on their faces and walked up to them and stuck their ears close to the drivers and the grins got bigger. So I dial them back down and they ask how much. Not for sale I said again. So the dude opens his wallet and counts out $100 dollar bills until I could not say no. They took them for their band and were thrilled to get them.

-

I would think the calculated values were there for a reason and the closer you stay to the OEM intent the better off you are. So you can't readily find a 13uf cap? A 10uf and a 3uf in parallel will give you that value and the added bonus is two like that will normally have lower ESR then the single 13uf. Higher voltage specs never hurts over OEM requirement and I get the best tolerance ones I can find at a reasonable cost. I can always come up with the exact value specked on the crossover schematic this way and never have to fudge the values. Building is always fun for me and the only way most of us can afford to try new things. Plenty of help on the forum when you run into trouble.

-

I am working on a horn that will fit where the K-400 does. It is not done nor tested but it is in progress. I have a finished final version 14" x 7" x 6.5" deep horn of stacked Baltic Birch which is awesome but nothing as of yet ready to go for La Scalas unless you want to set the mid horn on top of your cabinet.

-

I would add to this make sure your woofer wire can't lay up against the basket or you will get a buzz at times that you can hear and will drive you nuts trying to figure it out. I have had some from Klipsch that did so and it was audible at times.

-

Last picture on my post should not be there. I tried a few times to delete it with no luck. It is my "work" bench with a beat up KP-480 crossover and the HISM crossover and the required caffeine laden drink on hand.

-

OK @babadono here is your thread. We have all seen the Slants before so for the sake of preserving space for future pictures I will omit this. Anyway you get the back cover loose and the first thing I do is remover the K-55-V driver. It makes all the rest of the work easier to not have to maneuver around this. In any case now that it is removed you need to replace that old rock hard gasket. Kinda tough to get them out sometime but now is the time to replace them. Crites sells these. Next up is the tweeter. Sorry for the poor picture but you all get the idea. Take that old dog barker out and save it for resale on EBay. While you are at it there is another thing you need to take care of. Sometimes wires can lay up against horns or speaker frames and can at times make an audible noise you will catch real grief over trying to figure out where it comes from. In this case the OEM tweeter wires on both boxes was laying right on the mid horn. I have no idea if it really did cause noise and eliminated the potential problem as a matter of precaution. So the answer to that is to route the wire so it will never do so again. I take one of those nylon capacitor clips and use it as a guide as pictured. Now while you have that box open this is the time to check that all the driver and horn mounting screws are tight. While you are at it because you care do things like wipe the powdery stuff off the old woofer back and check for debris and remove it all. Yeah I know no one will see it but do it right anyway. On to the crossover. I silicone all capacitors in now. I guess hot glue would be no problem except I have seen capacitors work loose from that. I have never seen ones loose from silicone. I used to use those clips and cable ties until I found they dented the side of the caps over time and decided that I would avoid potential damage by not doing that anymore. So yes you have to wait for the silicone to set up but surely you can find something to do while you wait. First up the original crossover. Get rid of the Zeners as you will not need them with the SMAHL's and silicone those suckers in. While you are at it check the coil screw to make sure it is brass or stainless and not magnetic. Both of these had zinc plated steel and had to be replaced. Yes the steel screws change the value of the coil and need to go. Here is the finished crossover and you are good to go for the next 40 years. By the way I have a pile of obsolete out of spec parts that I am throwing out again if anyone wants them. You pick up shipping and I will send them.

-

That is a strange answer. Get rid of a great speaker and replace it with a lesser one and still have to decide on the amp. OP I would not worry about buying more and would just use what you have. Those PA3's will do just fine pushing those H4's. If you decide need another amp I have migrated to Crown XLI800's and they sound great and are dead quiet. I push some big gear with these at times and often have smaller boxes hooked up to make sure they are right before I sell them off. $275 each.

-

FOR SALE: Klipsch Heresy Slant Monitors near Nashville

Dave A replied to Dannyelectro's topic in Garage Sale

Getting into these today and next to the AA is stamped H I which was not clear in the picture. I figure they had AA labels and just did the save money thing and used those AA labels for more than one speaker. -

FOR SALE: Klipsch Heresy Slant Monitors near Nashville

Dave A replied to Dannyelectro's topic in Garage Sale

You go lower then the recommended crossover point with drivers you cant feed them full power any more. -

FOR SALE: Klipsch Heresy Slant Monitors near Nashville

Dave A replied to Dannyelectro's topic in Garage Sale

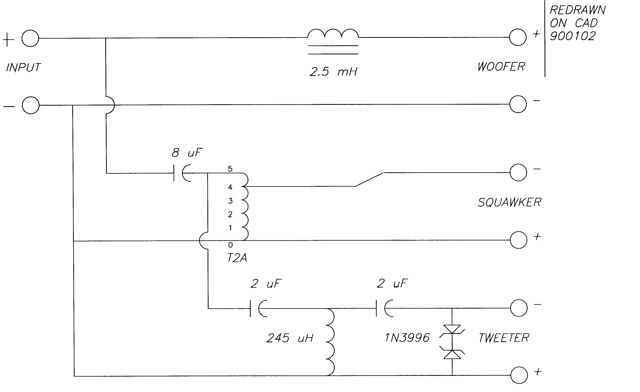

I know the tag says that but look at the HIE schematic. Could easily be two 4uf caps for the 8uf value and it does have zeners. -

FOR SALE: Klipsch Heresy Slant Monitors near Nashville

Dave A replied to Dannyelectro's topic in Garage Sale

Will do. This one will be pretty simple as I am not touching the cabinet. Recapping the crossovers and installing SMAHL's will be it but I will post on it. -

FOR SALE: Klipsch Heresy Slant Monitors near Nashville

Dave A replied to Dannyelectro's topic in Garage Sale

Yes enclosed in a cabinet with no ports. Recap and SMAHL's on the way. Got a single KPT-480 sub I am restoring to go with them. -

FOR SALE: Klipsch Heresy Slant Monitors near Nashville

Dave A replied to Dannyelectro's topic in Garage Sale

I am going to put a little magic on these great little speakers. Kind of curious to see the crossovers too as I am not used to 2 cans for the 13uf capacitor. -

FOR SALE: Klipsch Heresy Slant Monitors near Nashville

Dave A replied to Dannyelectro's topic in Garage Sale

How often do I only have to drive 20 miles each way for speakers!! SOLD -

I have a new myth to contribute by the way. Claude started a thread that was only going to be on myths.

-

I buy 4' x 8' sheets now which are just as common here and less waste. But yes 5' x 5' was all I knew about and asked for until I was out in the ware house one day and saw a stack of 4' x 8'.

-

I needed to add something here. I had one sheet of this material. The outer layer was thin and splintered with terrible pullouts no matter what type of cutter or saw blade I used. You could not sand this much at all without going right through the outer layer. It has some sort of resin/epoxy brown crap to fill voids and not football patches like BB. It weighs FAR less per cubic inch volume. I can put a piece of BB out there in my driveway under my trailer tongue jack and a year later it is still intact and though the outside is a bit etched it did not rot nor de-laminate. A piece of that chinese junk just sitting outside will fall apart in no time with the weather. There are places where the ply layers meet that actually have folded sections and then mashed to thickness. I have never seen anything but complete uniformity with the plys in BB. A local lumber yard had this and it looked good so I tried it one day. They were clueless about what BB really was and just accepted the label the Chinese put on their crap. I brought them a piece of real BB and their fake stuff to show them why I would NEVER be buying that garbage again. I have no idea what the chinese stuff is made from as there are such huge differences in the end result from their plywood vs BB plywood.

-

I have never seen that material though I have seen some chinese fake Baltic Birch which is truly odious to work with and a true third rate imitation of the real thing. The only Baltic Birch I have ever purchased came from reputable large plywood suppliers around Nashville and it was imported from the Baltic region made from Baltic Birch trees and had the exterior grade adhesive used and is basically uniform in appearance and void free. I have never been offered Baltic Birch that was not exactly that from my two vendors. I would say that if it is labeled Baltic Birch it must be made in the Baltic area with Baltic Birch trees and the correct glue. Anything else is Birch plywood irregardless of ply count and uniformity. BB is different then any other plywood I have used from the weight to how it cuts and how it holds up under stress and exposure to water. I have asked my two vendors if there is anything else like it and they say no. If they could find it and buy it they would have done so. Regarding the quote from @HDBRbuilder. Tooling has advanced a LONG way since he retired. I figure back then they were using straight flute soldered carbide router bits which are a poor substitute for the current helical solid carbide end mills in use. Also with the advent of CNC routers you can run the right rpm's to keep from getting to hot and still cut just fine and fast for production.

-

I would be curious to know how fast and deep he was running those bits and what type of bit, straight or helical for instance, he was running..

-

I have looked for this but have not found any locally. I hope to try this out some day and it appears to be the only possible alternative to BB quality wise.

-

Agree 100%. You build a correctly sized bass bin matched with 12" woofers, like perhaps the 400 watt Eminence Kappa 12A, and it is as close to pure horn distortion free bliss as you will get. Explosions and drums are far more precise as is everything else withing the range of your bass bin output. There is no mushy sound from something like this. My days of wanting 15" woofers are over except for the Super MWM's which also happen to be made out of 25MM Baltic Birch and do really well with K-43's.

-

Happy to help someone who likes to do things with his hands.

-

Yes due to the much heavier side panels. The same would be true for 1" plywood and especially 25mm BB. Having replaced some LS sides with 25mm Baltic Birch I can assure you the MDF is not the secret weapon but the thickness most assuredly is.

-

@ArmandCroft Have you ever used something like Vectric Aspire to generate your own files from pictures?

-

I have answered this specific question for you more than once and I do not intend to do so again because you did not hear me the first time and you will not hear me this time. You are quite tedious and I think I am going to forgo discussions with you. They always end up in the same place with near photocopied responses by you.