John Warren

Regulars-

Posts

2263 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Events

Gallery

Everything posted by John Warren

-

I'll leave that to you given you are projecting yourself as an expert. Never thought they sounded "so good".

-

Thank you! Multiple projects including amp, test gear restorations, rebuilds and ground up new makes keep me happy.

-

At the risk of burdening you with finding another way to disagree with me, I shall agree with you.

-

Nice job!

-

Luckily the circuit survived the destruction of the safety cap, it opened. They're designed not to catch fire given the application across mains voltage (CL-X1 and X2). These capacitors have a reputation for failing. They're in all sorts of vintage test gear.

-

-

-

So, removed the 2x50uF, cleaned the mess and replaced the RIFA with a fresh X2 and a couple of new 50uF, 450V, low ESR Lelon's.

-

The EMI filter cap (a RIFA) bursts. This is one across the mains, class X2 safety cap. Removed to show board distress. Note it did get hot enough to melt the shrink on the filter cap (2x50uF. 400V multi-section).

-

-

BANG!

-

Recently acquired an early 80s Philips scope that appears to have very little use and immediately pressed it into service. Ran absolutely flawlessly for about 10 hours then...

-

Brazing is actually a quite different as well. In a proper braze joint, there's a metallurgical diffusion zone between the part surfaces and braze alloy where limited solubility exists. Braze alloys are selected to provide diffusion at the interface. Typical braze furnace cycle is to ramp up to braze temperature, hold a few minutes, then cool to an intermediate temperature and then long soak at the intermediate temperature to facilitate the diffusion process. Braze joints can be very close to parent metal strength for some alloy systems like Titanium based for example where the braze alloys are "fortified" with Zirconium and Vanadium, elemental additions that provide potent strengthening effects There's vacuum furnace brazing, dip braze, torch brazing, induction brazing.

-

Soldering is not like welding, it's an entirely different joining process. Welding consumes both part surfaces being joined, solder is an alloy introduced at the joint that is melted and designed to wet the two parts being joined but does not, under any circumstances, consume or otherwise "melt" the parts being joined. Welding temperatures are significantly higher than the two materials being joined, this promotes solubility and homogenization of the weld pool. Welds also have mechanical requirements that are different than soldering. Joining methods: Soldering Furnace brazing Welding - many ways, resistive, friction stir, inertia, TIG, MIG, He-assist, plasma Diffusion bonding Explosive bonding

-

Roger's been dead for some time now, curious to know who's keeping the website up.

-

Why No Bandpass Filtering on Woofers?

John Warren replied to Peter P.'s topic in Technical/Restorations

The most popular loudspeakers are ear buds. -

Why No Bandpass Filtering on Woofers?

John Warren replied to Peter P.'s topic in Technical/Restorations

The voice coil dissipates applied AC power regardless of the mechanical limitations of the suspension. -

Why No Bandpass Filtering on Woofers?

John Warren replied to Peter P.'s topic in Technical/Restorations

-

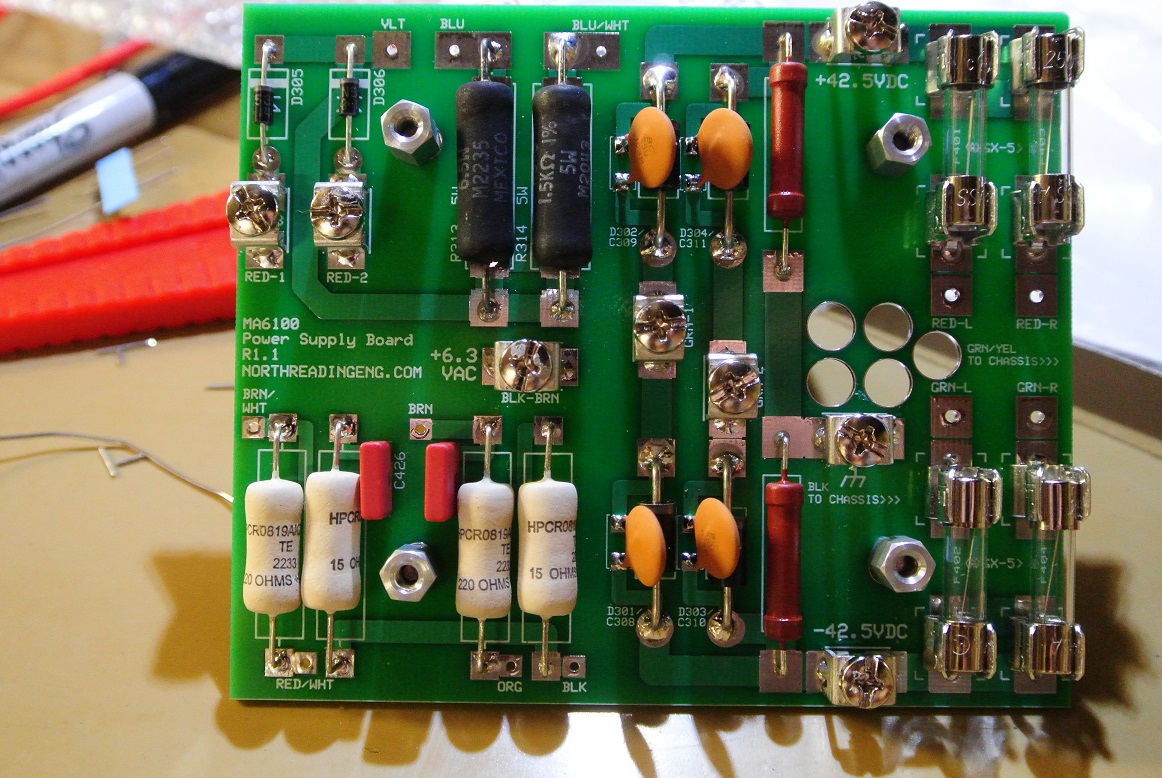

I completed the preamp module some time ago, got involved in another project. Here's the module, based on a couple of 12AX7s. Requires a -45VDC supply for the tube heaters and a 250VDC supply for the anodes. Has treble and has contour pots located on the board. Caps are either NPO or film. The Fluke is showing anode voltage. Two channels on one board. Can be assembled in a morning. Sounds pretty good!

-

One would also require a filament supply (VAC or VDC?), 350VDC supply that may also be on a PC board. There's also power transformer, OT transformer, chassis/cage. Are the tubes mounted to the PC board? or is the board for component and wire management only?

-

LOUDSPEAKER ENCLOSURES (CONT.) The show was not crowded, and we spent well over 30 min in many of the rooms we visited, sitting in the "sweet spot". There were a number of 2-way systems based on the AMT which I found to be excellent reproducers. Incorporating the self-damping characteristics of composite enclosures, 8 and 10" woofers are capable of high volume, articulate bass output well down to the lows in a moderately large listening room. My favorite? The Fink Team "Borg". In the hotel room, with some drapes and bass traps here and there I found this system to be excellent sounding. They're in the mid $30k range. The enclosure is an engineered laminate. They also make a system based on a 15" woofer which is on display at the dealer here in Boston. Website for this system is interesting read with a few white papers that show what's going on inside the box. Borg – Fink Team

-

Loudspeaker Enclosures MDF, Particle Board, Plywood enclosures are gone (thank goodness!). The top tier suppliers today have transitioned to composite structures including mineral casting, structural laminates and, of course, Aluminum plate. The enclosures materials are where the engineering is most intense and where the distinctions will be made. The small speaker below, made by Kroma (a German supplier) was an example of what a mineral cast enclosure provides. $16k/pr with stands, this little speaker was outstanding. The woofer surround is specifically designed to break-up standing waves that ripple along the cone. This wasn't my favorite at the show, it was the one I was most impressed with. Great reproduction at very high volumes. Upper mids and HF handled by the AMT. Many suppliers are transitioning to the AMT as well.

-

The Doubletree by Hilton in SeaTac is adjacent to the SeaTac International airport, it's a large, somewhat dated hotel. There was a reduced rate for show attendees ($179/night + $22.38 room tax/night + $2 tourist assessment fee/night). Wife and I stayed four nights = $814 which, for a large city, isn't bad. SeaTac the city is the airport, airport support services, hotels and a few small businesses. There's nothing really to do there but public transport is available, light rail, and it's at the airport and it takes you directly into downtown Seattle. You can walk to the airport too (it's that close) from the hotel or you can ride the hotel shuttle to the airport. The light rail is not expensive either (compared to Boston's rail service into the city, the MBTA aka the "T") and it's clean and on time. It's a 45min ride into downtown. Along the way you're traveling thru a few sketchy parts and there's always addicts and homeless to keep you company.

-

I was there for the entire event, Seattle WA and will report my observations and thoughts but... if you've never been to Seattle, don't bother. Seattle has a problem that is getting WAY out of control. It's a beautiful part of the US that has been overtaken by the homeless, many actually quite violent, bold. They toss excrement, confront poor folk just trying to go about their lives. They are EVERYWHERE. They're also where tourist congregate, the city does nothing to protect citizens, no cops anywhere. There was even an event in the lobby of the Doubletree at SeaTac, the hotel where the show took place. Then there's the addicts, young, male and female, mostly white. Strung out on either meth or heroin or glue. It will be a cold day in Hell before I go there again.