Jim Gregory

Regulars-

Posts

275 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Southern Gentleman

-

My System

Front End :

Auralic Aries G2 Streamer

Auralic Vega G2 DAC (with Hoer-Wege PSU )

Auralic Leo GX Clock

Marchand XM44-4AA electronic crossover

High Frequency:

18x10 horns Radian 760 Br Pb drivers

DaveA SMAHL tweeters

Don Sachs D2 preamp

(1) pair Nelson Pass Aleph 2 amplifiers

Mid High Frequency:

Klipsch 402 horns Celestion AXi 2050 drivers

Cary Audio SLP-05 Preamplifier

Cary Audio 805C Monoblock Amplifiers

Output tube: Psvane 845 ACME Premium

Driver Tubes:

2020 WE 300 B

Input Tubes:

6SL7

NOS RCA/GE 5691 Red Base Gray Plate 8% matched

Mid Low Frequency:

Inlow 135hz Horns with B&C 8PE21 drivers

Parasound Halo P5 preamplifier

(1) pair Nelson Pass Aleph 2 amplifiers

Mid Low Frequency:

Klipsch KPT 415’s

Pass Labs X0.2 preamp

(2) pair Nelson Pass Aleph 2’s amplifiers

Low Frequency:

(2) Danley DTS 10 Subwoofers

Crown XTI 6002 amplifier

(2) REL Stentor ii Subwoofer

(2) Audioquest Niagara 1200

AC: PS Audio AC 12

HF Speaker Cables: Duelund DCA16GA

LF Speaker Cables: SignalCables Silver Reference

Interconnects:

Balanced:

Cardas Golden Reference

Cardas Golden Cross

RCA:

Belden 8402

Contact Methods

-

Yahoo

Jimedgregory55@yahoo.com

Recent Profile Visitors

2244 profile views

Jim Gregory's Achievements

Forum Veteran (4/9)

291

Reputation

-

I would like advice on the best position of the Pope tubes. I have a Cary SLP-05 and plan on using the Pope tubes in it. Cary has stated to get full effect (if you are not going to replace all six at once) positions 1,2,4 and 5 should be replaced, as these are the gain stages. Position 1&2 are L&R channel positive phase gain – buffer. Position 4&5 are L&R channel negative phase gain- buffer. In your opinion which position (1&2 or 4&5 ) would be the better option ? Kind regards Jim

-

-

-

PM sent

- 1 reply

-

- tweeter

- klipschorn

-

(and 1 more)

Tagged with:

-

-

My room is 28’x16’x12’. In the past I have had 3 Klipsch speaker setups. Klipsch KP 301 Klipsch KP 301ii & KP 115X Klipsch KPT-456 with 2 Rel Stentor subs Klipsch KPT-942 with 2 Rel Stentor subs and currently a modified version of the KPT 535-4-T My normal SPL is 85db however I have listened to some rock and symphony passages up to 95db. I find the sound quality in each setup to be quite good. With each step the biggest difference was the increased size & depth of the soundstage. Enjoy the Music 🎶

-

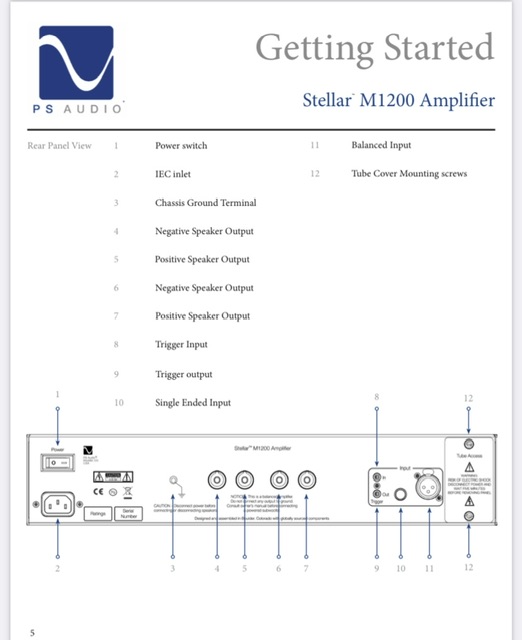

Thanks Peter for attempting to assist me. I called PS Audio today and “yes” I can connect a 4ohm load to each pair of speaker outputs. Like if I was configuring it in a bi-wire mode.

-

Thank you for the response Peter. I understand that connecting (2) 8 ohm drivers together in parallel equals a 4 ohm load. If a do this to each pair of speaker outlets on this amplifier in a bi-wire configuration is it still a 4 ohm load on the amplifier ? Or would it lower ?

-

The speakers in the KPT 415 are 8 ohm speakers

-

If I connect (2) of the 15” drivers “parallel”(KPT 415) to one pair of speaker outlets on the amp and the other (2) set of 15” drivers to the other pair of outlets on the amp. Is this a 4 Ohm load on the amp ?

-

I too have had both Tidal & Qobuz and prefer Qobuz for SQ. Qobuz also pays the artist a higher compensation. Tidal has the edge for a broader artist & album selection. But I opposed the direction of market manipulation Tidal was engaging.

-

Pets are only pets when you first bring them home. With time they truly feel more like family. I think they know that as well as you. Sounds like you both shared some great times together. So sad for your loss Sir.