-

Posts

1148 -

Joined

-

Last visited

Content Type

Forums

Events

Gallery

Everything posted by oldred

-

Arash, I am really enjoying seeing your progress. As far as the broken tap....Here in the USA ...in the machine building trade.... our saying for broken taps ....is ....(Shit happens)......and it has happened to all of us. I have been a machine builder ever since I finished my apprenticeship in 1980.....a long .........long time ago. Keep the pics coming....I am really looking forward to a video of your test winding. Once again....Great job, George,

- 45 replies

-

- 1

-

-

- inductor

- coil winding machine

-

(and 1 more)

Tagged with:

-

One word........WOW George,

-

https://chicago.craigslist.org/chc/ele/6160971483.html George

-

.thumb.jpg.ef78732a731094d2f33cd0c347737e86.jpg)

Pulled the trigger today.......forte 3's here I come

oldred replied to Scrappydue's topic in 2-Channel Home Audio

+ 1 to that. We are looking forward to it. George -

Arash, Great work. The design is what I call a simple elegance. What you have done is built a lathe head (love the 10 mm 3 jaw chuck). Then you use the ball screw for the winding progression. What do you have in mind for a control system. I see in your Solidworks assembly you have an encoder mounted to take of turn counts. How do you plan on braking the turn count motor. George,

- 45 replies

-

- 2

-

-

- inductor

- coil winding machine

-

(and 1 more)

Tagged with:

-

You probably know every pair of Klipsch speakers for sale ....ON THE PLANET.... ! George

-

I wonder what it is... Everything I have been reading...says it sounds good. George,

-

Are you sure ....it was correct gfa-5006-ug.pdf George,

-

Adcom GFA 5006 is only 50 X 6. Did you bridge them? I'd recommend a GFA 7605 or GFA 7607 ...125 X 5....125 X 7. George,

-

Could not have said it any better. Be safe. George,

-

Very nice. George

-

My thoughts exactly.....still a great deal George.

-

well ....how do they look??. The uppers look like walnut, Suggestion....go to Dollar General buy some poster board and blue tape cut the poster board in sheets and cover the drivers ...if you do not want to remove them. Get them looking nice ....then use Watco rejuvenating oil...If you need to refinish risers you my need to pick up stain to match....best match I found is Minwax gunstock... They are getting there PS....nice mattress George,

-

.thumb.jpg.ef78732a731094d2f33cd0c347737e86.jpg)

Happy/Sad introduction to the Klipschorn family

oldred replied to AHall's topic in 2-Channel Home Audio

AHall ...welcome to the form. Great story. George, -

No. George,

-

They use to be black...The walnut veneer was under the black......needed to do risers cause they were oak.

-

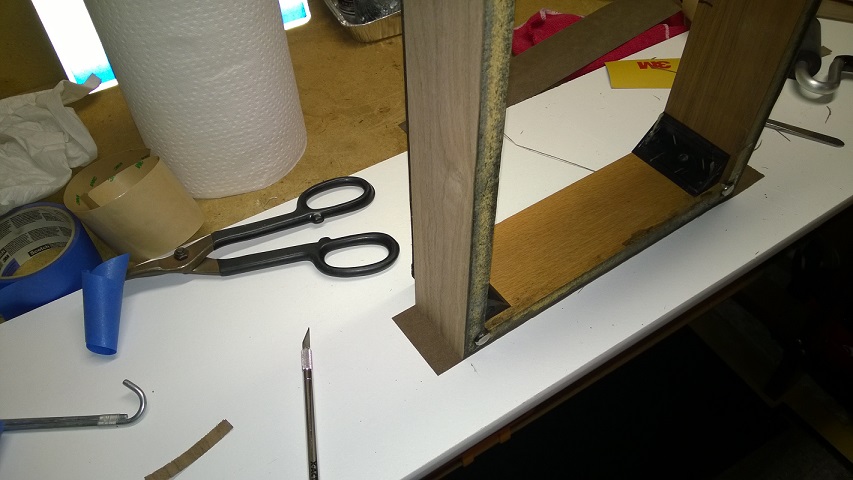

Risers are pretty easy to fix...The brackets can be reattached with a hot glue gun...you could drill a couple small holes through the the plastic corner brackets and screw them on. Just use short enough screws ( not to break through the outside of the risers). Taking off all the old veneer ...you will need a heat gun and a good L shaped scraper...and a little work (patients). You can get adhesive backed veneer from Rockler. Just cut into 2 3/4 inch strips and re veneer the sides.....staining to match is not so easy....use some of the veneer scrap pieces to match . See photos. George

-

Wow !!! Great room.....What is the thing sitting on the left Khorn? George,

-

I just love going to shows like Axpona ...and I do go every year...then I go home and listen to my working mans system ( chorus II's and 80's m series Yamaha ) and say ..."Wow I saved a lot of money" High end is not always better....looks nice. Thanks, George

-

Good question

-

Most likely Chorus II's. George,

-

Yea....just what I was looking for. Looking forward to checking it out.... George,

-

PM sent George,

-

.thumb.jpg.ef78732a731094d2f33cd0c347737e86.jpg)

Best way to connect two amplifier sources to one pair of speakers

oldred replied to justin240's topic in 2-Channel Home Audio

I bought one of these. http://www.ebay.com/itm/TC-7220-2-Way-Amp-Amplifier-Speaker-Selector-Switch-Switcher-Comparator-Router-/391073502625?hash=item5b0dcc15a1:g:ccgAAOSwPhdU9yws George,